Iron Casting & Machining Supplier in China – YBmetal

A trusted iron casting China partner and precision castings supplier

About YBmetal – Professional Metal Casting Supplier

One-stop Metal Casting Services

YBmetal Solution is an engineering-led manufacturing partner for high-quality gray iron, ductile iron, and cast steel components in China. Our on-site team plans the process, qualifies and manages the right foundry cell, and runs production under our control—metallurgy, tooling, CNC machining, and inspection—through to export. Acting as a single accountable supplier, YB Metal delivers PPAP-ready parts with full documentation and ships to the USA, Germany, the UK, Australia, and more.

- ✅ Access 15+ verified foundries

- ✅ Engineering & drawing support

- ✅ Quality inspection & lab tests

- ✅ Fast sample turnaround

- ✅ Full shipment support

Metal Casting Products & Services

Industries we serve

Regularly Supplied Casting Parts

Thin-Walled Complex Cavity

QT450-12 4.77 KG

Machine Tool Components

FCD600-3 432 KG

Casting Connecting Bracket

FCD450 35 KG

Cast seeding point

QT450-12 2.7 KG

Semiconductor Components

3.5 KG

Traction Sheave

QT600-3 8.73 KG

Heavy-Duty Cast Bracket

EN-GJS-550-6 73 KG

Iron Casting Parts

QT500-7 35 KG

Our Casting Process – From Inquiry to Delivery

- ✅ Requirement Analysis – We review your drawing & spec

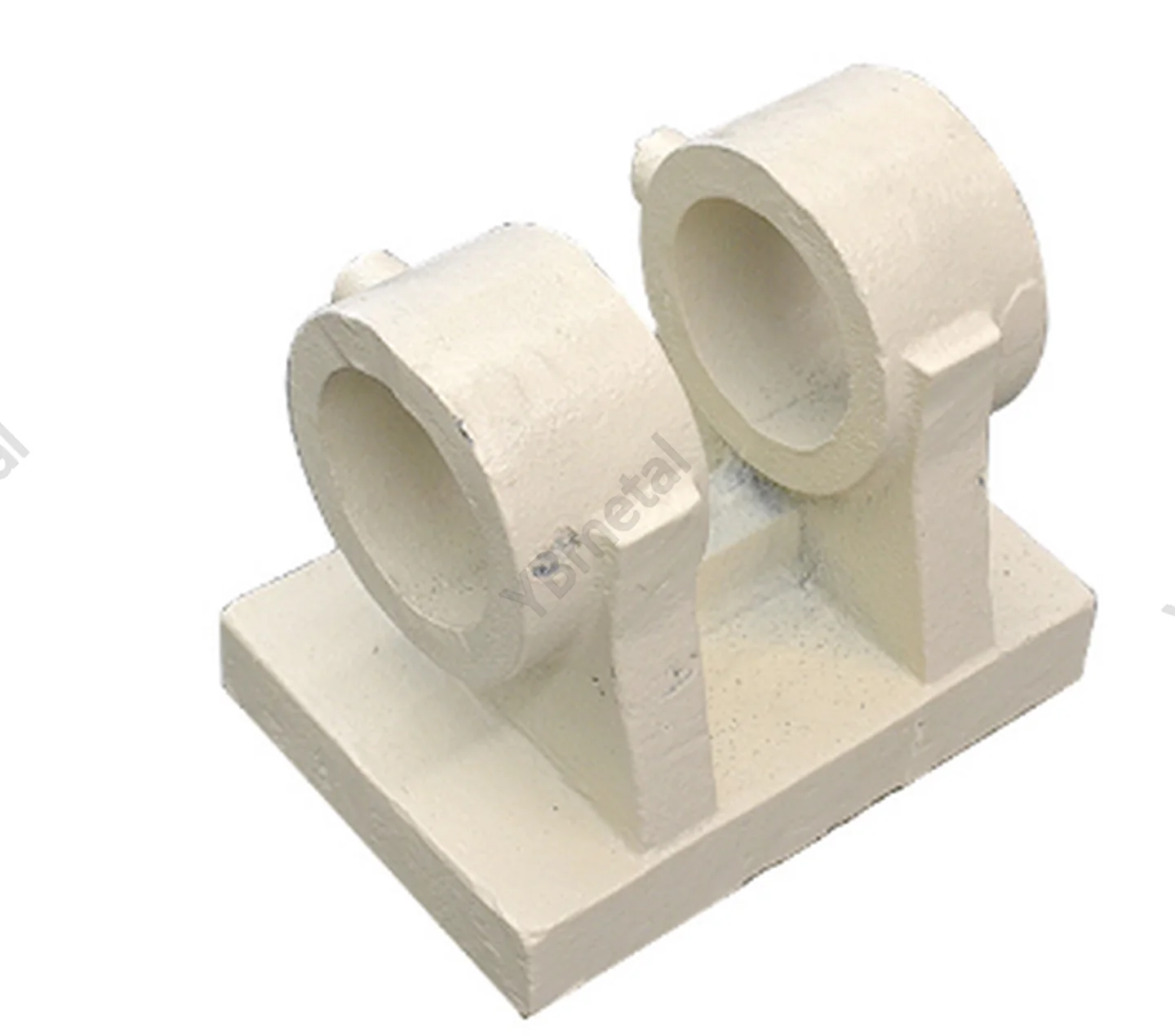

- ✅ Casting Method Match – We select the best-fit foundry based on process, price & lead time

- ✅ Quotation – One quotation, multiple supplier options

- ✅ Sampling – We arrange samples for inspection

- ✅ Production & QC – Full production monitoring

- ✅ Shipping & Documents – We manage logistics, customs, and paperwork

All castings come with:

Material Certificates, Dimension Reports, Third-party Inspections (on request)

Why Choose YBmetal

- ✅ Delayed replies

- ✅ Language/culture gaps

- ✅ Unclear production status

- ✅ Quality inconsistency

- ✅ Communication breakdown during shipping

- ✅ No Local Oversight

- ✅ Bridging Technical

YBMETAL, as a trusted Manufacturer of Machined Iron Castings, bridges this gap. We reduce risk with a transparent, tested end-to-end casting sourcing solution.

Certifications & Quality Assurance

We only cooperate with ISO 9001 / IATF 16949 certified foundries in China.

All castings can meet ASTM, DIN, GGG, JIS, or BS standards.

- Spectrometer and C–S analyzer for chemical analysis

- Hardness, tensile, and impact testing for mechanical properties

- Dimensional checks using CMM and 3D scanning

- Optional UT, MT, RT based on customer specs

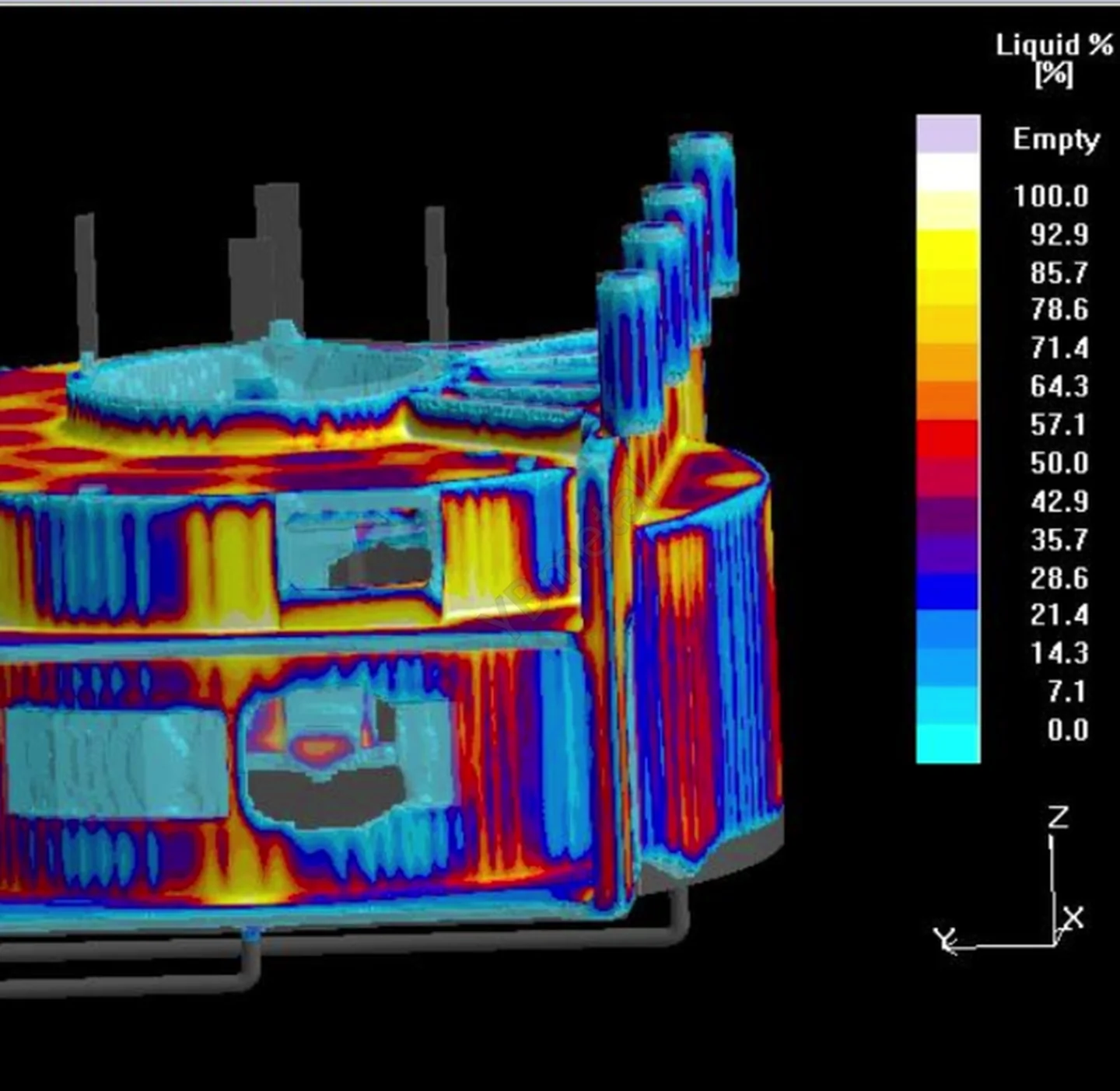

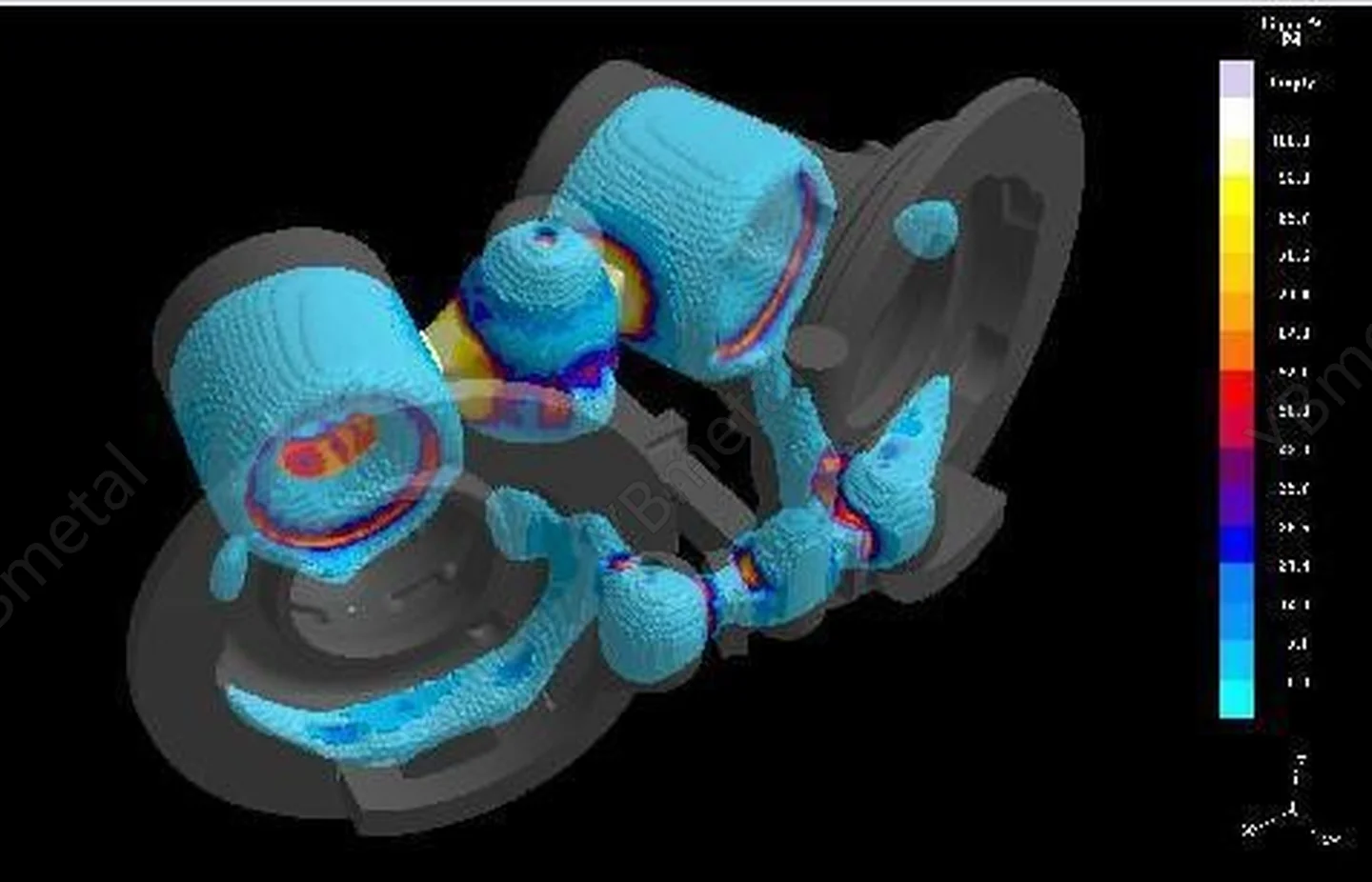

- Mold Flow and Filling Simulation

- All results are traceable by batch, operator, and machine

- Iron composition and temperature are digitally controlled in real time

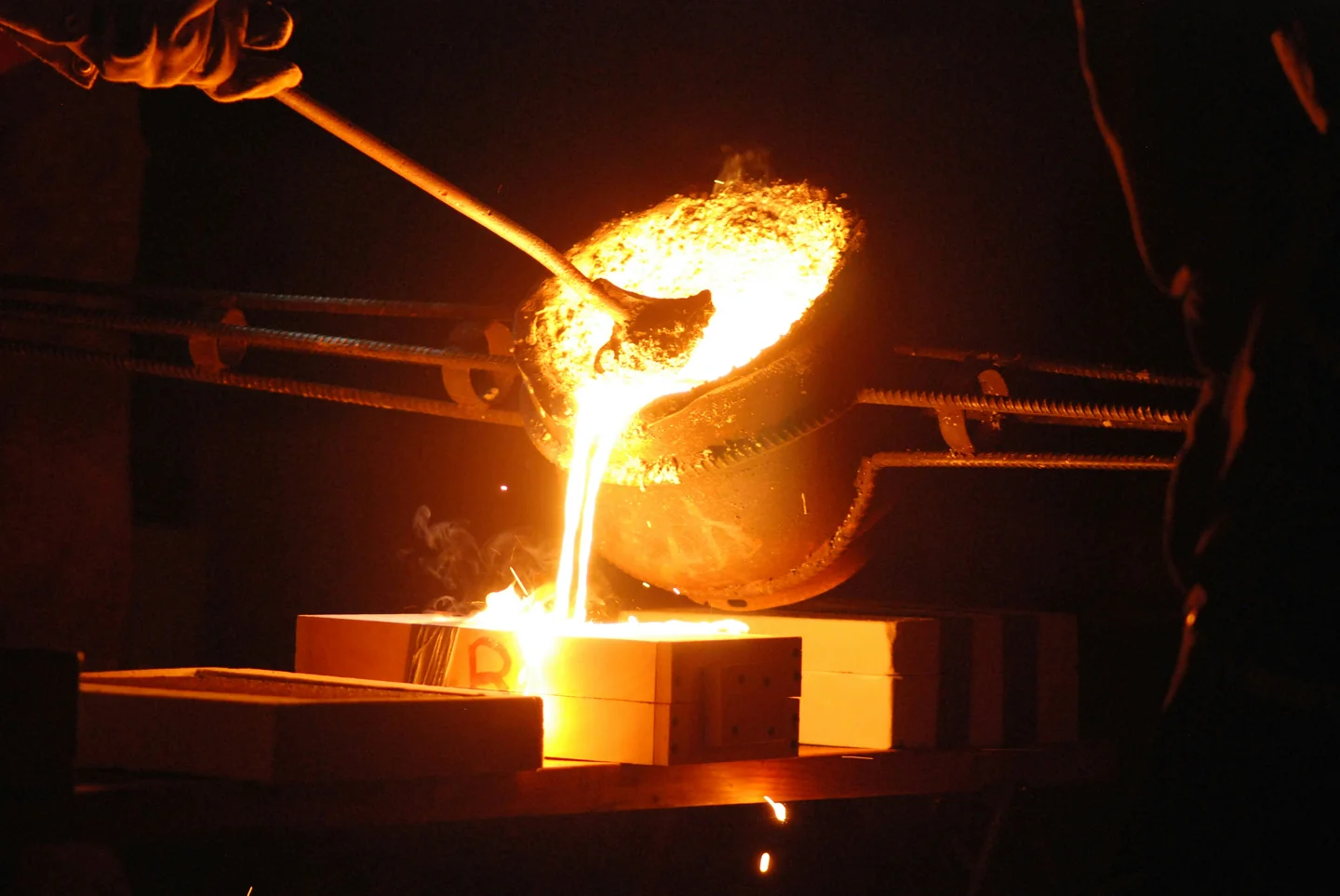

- Molding and pouring parameters are precisely managed

- CNC precision machining is monitored for accuracy and tool wear

- Full production data linked to operators and equipment

- DOE is used to identify and control critical process factors

- Cp/Cpk metrics tracked for process capability

- Closed-loop system for fast issue resolution

- Root cause analysis ensures continuous improvement

Ductile Iron Foundry in China

Ready to Start Your Iron Casting Project?

Send us your drawings or part photos, and we’ll prepare a tailored sourcing plan, including foundry recommendations, a cost estimate, and a sampling lead time.