Ductile Iron Casting Supplier for OEM Components in China

YBMETAL provides custom ductile iron casting for global OEMs requiring strong, impact-resistant, and pressure-tight components. With in-house CNC machining and decades of foundry experience, we supply nodular iron parts from 1 kg to 3,000 kg, fully machined and certified to international standards.

What Is Ductile Iron Casting?

Also known as nodular cast iron, spheroidal graphite iron, or SG iron, ductile iron features graphite nodules instead of flakes, giving it higher tensile strength, ductility, and shock resistance than gray iron. This makes ductile iron ideal for safety-critical, high-load, and pressure-tight parts in demanding industrial environments.

- QT450-10, QT500-7, QT600-3 (GB/T 1348)

- EN-GJS-400-15, EN-GJS-500-7, EN-GJS-600-3 (EN 1563)

- ASTM A536 60-40-18, 65-45-12, 70-50-05

- GGG40, GGG50, GGG60 (DIN 1693)

International Ductile Iron Grades Comparison – Global Standards Equivalents

| Country | Standard | Equivalent Grades of Ductile iron (SG Iron, Nodular Graphite Iron) | ||||||

| ISO | ISO 1083 | 400-15 400-18 | 450-10 | 500-7 | 600-3 | 700-2 | 800-2 | 900-2 |

| China | GB 1348 | QT400-18 | QT450-10 | QT500-7 | QT600-3 | QT700-2 | QT800-2 | QT900-2 |

| USA | ASTM A536 | 60-40-18 | 60-42-10 65-45-12 | 70-50-05 | 80-55-06 80-60-03 | 100-70-03 | 120-90-02 | — |

| Germany Austria | DIN 1693 | GGG40 | — | GGG50 | GGG60 | GGG70 | GGG80 | — |

| European | EN 1563 | EN-GJS-400-15 EN-GJS-400-18 | EN-GJS-450-10 | EN-GJS-500-7 | EN-GJS-600-3 | EN-GJS-700-2 | EN-GJS-800-2 | EN-GJS-900-2 |

| Japan | JIS G5502 | FCD400 | FCD450 | FCD500 | FCD600 | FCD700 | FCD800 | — |

| Italy | UNI 4544 | GS370-17 | GS400-12 | GS500-7 | GS600-2 | GS700-2 | GS800-2 | — |

| France | NF A32-201 | FGS370-17 | FGS400-12 | FGS500-7 | FGS600-2 | FGS700-2 | FGS800-2 | — |

| UK | BS 2789 | 400/17 | 420/12 | 500/7 | 600/7 | 700/2 | 800/2 | 900/2 |

| India | IS 1865 | SG370/17 | SG400/12 | SG500/7 | SG600/3 | SG700/2 | SG800/2 | — |

| Spain | UNF | FGE38-17 | FGE42-12 | FGE50-7 | FGE60-2 | FGE70-2 | FGE80-2 | — |

| Belgium | NBN 830-02 | FNG38-17 | FNG42-12 | FNG50-7 | FNG60-2 | FNG70-2 | FNG80-2 | — |

| Australia | AS 1831 | 300-17 400-12 | — | 500-7 | 600-3 | 700-2 | 800-2 | — |

| Sweden | SS 14 07 | 0717-02 | — | 0727-02 | 0732-03 | 0737-01 | 0864-03 | — |

| Norway | NS11 301 | SJK-400.3 SJK-400 | — | SJK-500 | SJK-600 | SJK-700 | SJK-800 | |

Why Choose Ductile Iron for the Castings Project?

- ✅ High tensile strength and elongation: Achieves 450–700 MPa tensile strength and 10%+ elongation — ideal for fatigue and shock load conditions.

- ✅ Pressure-tight and impact-resistant: Graphite nodules enhance sealing performance, used in valves, pumps, and hydraulics.

- ✅ Good weldability and machinability: Better machinability than steel or gray iron; can be welded with appropriate preheat/postheat.

- ✅ Thin-wall and complex casting capability: Excellent fluidity allows complex geometries and reduced part weight without sacrificing performance.

- ✅ Widely used across industries: Trusted in automotive, construction, agriculture, mining, railway, and mechanical systems.

Limitations of Ductile Iron Casting

- ❌ Higher cost than gray iron: Due to alloying elements (Mg, inoculants) and stricter control, ductile iron has a higher production cost.

- ❌ Less wear resistance than alloyed steels: Not ideal for components exposed to constant abrasion without additional treatment or coating.

- ❌ Brittle at low temperatures: Toughness decreases sharply under freezing or cryogenic environments.

- ❌ Requires more quality control: Nodule formation and matrix control require careful melting, inoculation, and cooling management.

Limitations of Ductile Iron Castings

- Gearboxes, flywheels, engine crankshafts, brackets

- Valve bodies, pump housings, hydraulic fittings

- Axle supports, couplings, bearing caps

- Transmission and suspension parts

- CNC-machined ductile iron castings with documentation

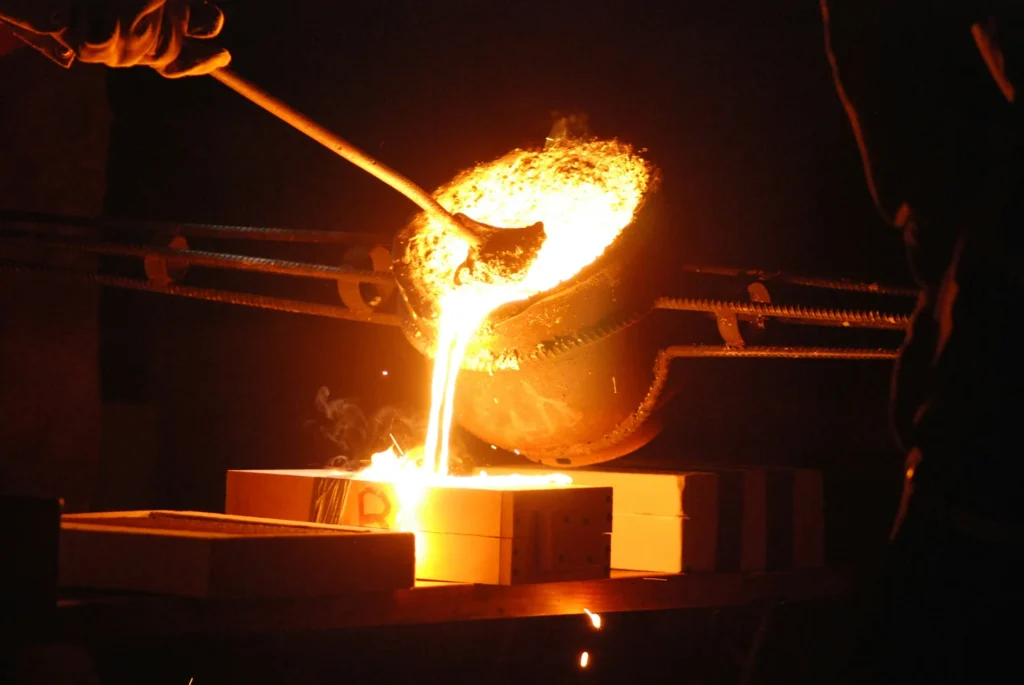

Our Ductile Iron Casting Capabilities

- Casting range: 1 kg – 3,000 kg

- Processes: Green sand, resin sand, shell molding

- Optional heat treatment, machining, and coating

- Material options: QT450–QT700, EN-GJS, ASTM A536

- Quality reports: Spectrometer, tensile, CMM, hardness, 3D scan

- Export-ready: Full packaging, PPAP, FAI, RoHS available

- Request a Quote

Trusted Ductile Iron Foundry in China

YBMETAL partners with ISO 9001 / IATF 16949 foundries and provides:

- Engineering review and DFM guidance

- Full documentation & inspection (CMM, PPAP)

- Fast turnaround and multilingual support

- One-stop ductile iron casting + machining