Precision Industrial Castings for Machinery and Heavy Industry

Precision Iron & Steel Castings for CNC Machinery, Power Equipment & Industrial

YBMETAL delivers precision industrial castings for machinery and heavy industry solutions for global OEMs and system integrators. We specialize in machined cast iron and steel components for sectors including machine tools, power equipment, compressors, automation, mining, and material handling. From structural stability to wear performance, our castings are engineered to meet industrial-grade mechanical demands, with complete CNC machining, inspection, and quality documentation.

Benefits of Our Industrial Castings for Heavy Machinery

| Feature | Description |

|---|---|

| Heavy-duty mechanical performance | Gray and ductile iron castings for CNC bases, lathe beds, column frames, and spindle carriers — ensuring rigidity, flatness, and long-term stability. |

| Precision CNC machining compatibility | Gray and ductile iron castings for CNC bases, lathe beds, column frames, spindle carriers — ensuring rigidity, flatness, and long-term stability. |

| Full-process material traceability | PPAP, FMEA, CMM, and metallurgical analysis provided for repeatability and OEM compliance. |

| Flexible production & dimensional consistency | Supports sand casting, shell molding, and machining — from trials to full production — with short lead times and consistent tolerances. |

| ISO/IATF certified casting suppliers | Castings sourced from ISO 9001 / IATF 16949 certified foundries, with audits and verified material controls. |

Industries We Serve with Machined Iron & Steel Castings

| Lathe bases, column frames, and cross slides | Example Parts |

|---|---|

| Automation & Actuation Systems | Servo housings, robotic arm bases |

| CNC Machine Casting Supplier | Turbine parts, brackets, and generator mounts |

| Power Generation Equipment | Pump shells, crankcases, and cast fans |

| Compressor & HVAC Castings | Flanges, covers, brackets, and support parts |

| Mining & Bulk Handling | Wear plates, drag shoes, conveyor arms |

| General Industrial Machinery | Flanges, covers, brackets, support parts |

Common Iron & Steel Casting Parts for Industry

| Component Category | Example Parts | Preferred Materials |

|---|---|---|

| Machine Tool Structures | Crankcases, cylinder heads, and cooling jackets | Gray Iron HT250–300, QT500–7 |

| Power Equipment | Generator frames, turbine plates, motor brackets | Ductile Iron, Cast Steel |

| Compressor Systems | Conveyor brackets, bearing holders, and lifting arms | Gray Iron, Ductile Iron |

| Gear & Transmission Castings | Gearboxes, couplings, housings, bearing caps | ADI, QT600–3, Cast Steel |

| Material Handling Castings | Torque arms, trunnions, and bushing carriers | Cast Steel, QT700–2 |

| Pump & Valve Bodies | Volutes, impellers, valve housings, stuffing boxes | Cast Steel, QT500–7 |

| Custom Mechanical Parts | Torque arms, trunnions, bushing carriers | Lathe beds, column blocks, CNC bases, and tool carriers |

Choosing the Right Casting Material for Your Industrial Castings Components

| Functional Area | Recommended Material | Key Benefit |

|---|---|---|

| Machine tool bases | Gray Iron HT250–HT300 | Excellent damping, flatness, cost-effective |

| Load-bearing housings | QT500–7 / QT600–3 | Superior strength, machinability |

| Rotating & wear parts | ADI / Cast Steel | Excellent damping, flatness, and cost-effectiveness |

| Pump & compressor parts | QT450–10 / Cast Steel | Pressure containment, thermal stability |

| Vibration-sensitive areas | Gray Iron | Natural vibration absorption and dimensional control |

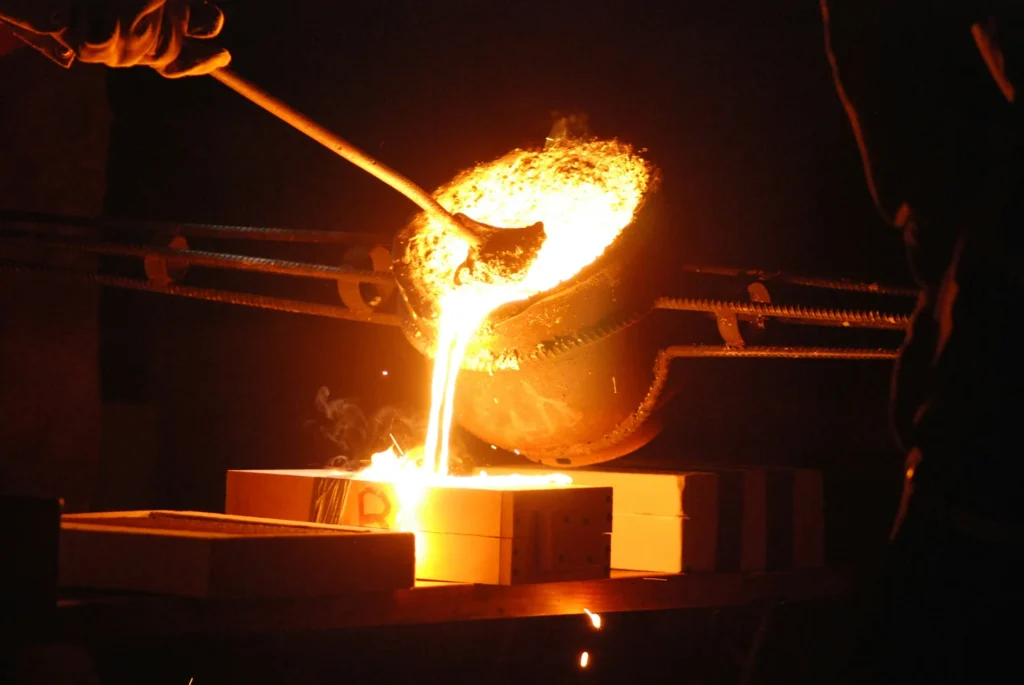

Ductile Iron Foundry China

Get a Custom Quote for Your Industrial Casting Project

Whether you need a machine tool casting supplier, a compressor housing manufacturer, or custom precision castings for industrial automation, YBMETAL offers engineering-driven casting sourcing services with:

- Fast quoting and prototyping

- Material & process selection support

- Consistent tolerances & machining-ready parts

- End-to-end project oversight

- Global delivery and export coordination

We’ll review your casting project and recommend the most suitable material and process, ensuring performance, quality, and cost-efficiency.