Iron Casting Quality Control & CNC Machining Inspection

Integrated Quality Control from Melt to Machined Casting

YBmetal ensures consistent, defect-free castings through end-to-end Iron Casting Quality Control, covering digital melt tracking, engineering simulation, foundry inspection, and in-house CNC precision validation. As a trusted iron casting supplier in China, we serve global OEMs with APQP/PPAP-compliant workflows, GD&T controls, and Six Sigma-based traceability systems.

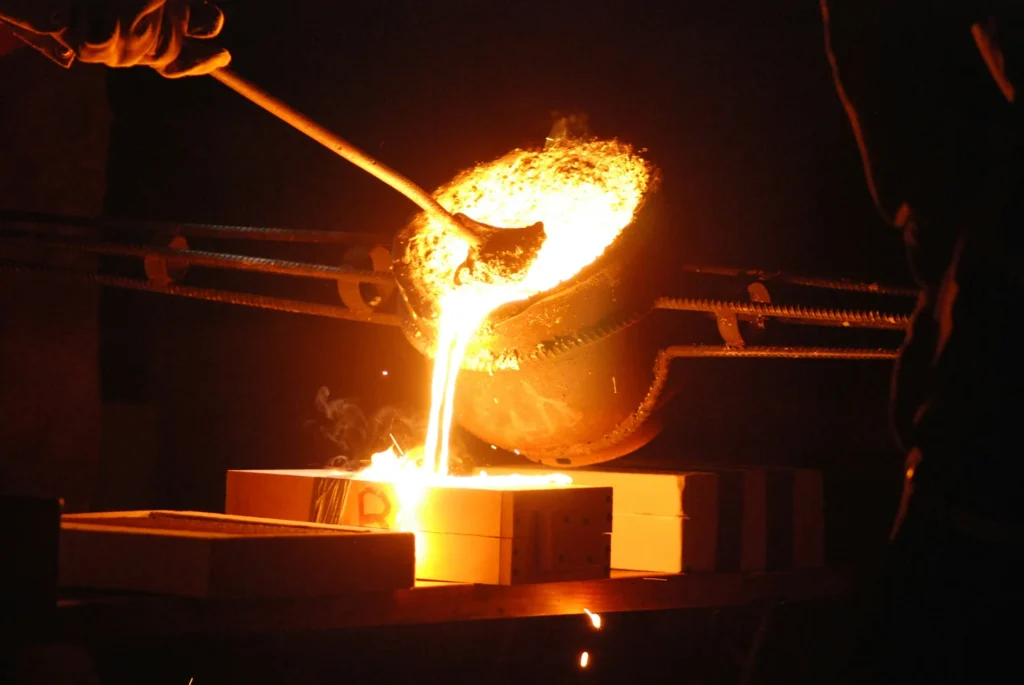

Melt Process & Metallurgical Control

Digital Melt Management

We utilize a digitally controlled melting system to ensure stable carbon and silicon control, real-time temperature management, and batch traceability. All data is archived and linked to product IDs, supporting root cause analysis and ISO-compliant documentation.

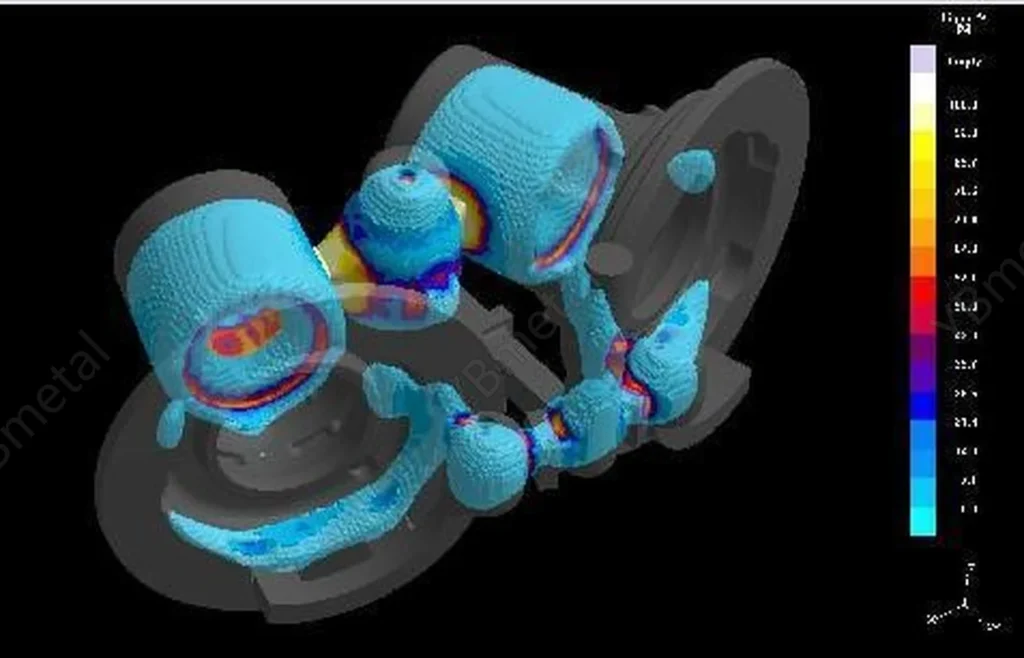

Process & Product Engineering

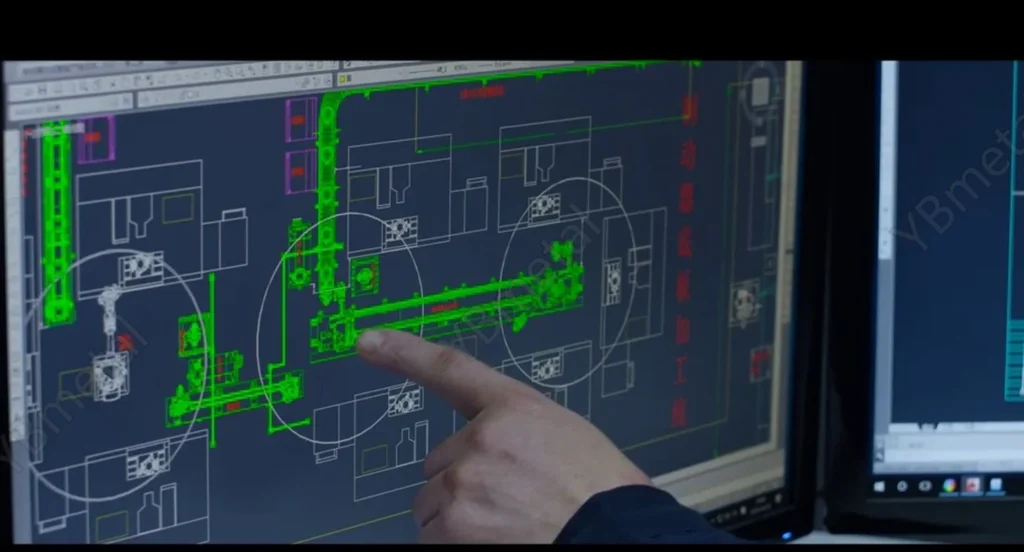

Our engineers leverage DFM, casting simulation, and Design of Experiments (DOE) to validate gating, cooling, and geometry decisions before tooling. This minimizes defect rates and ensures smoother sample approval.

Project Quality Planning (APQP / PPAP)

We implement a structured APQP process for all new projects, supported by full PPAP Level 3 documentation, including: ✅ Process FMEA & control plans ✅MSA, CMM, and SPC reports✅Dimensional and material certifications✅First article inspection and CoC

Data-Driven Quality Control

YBmetal system integrates 6Sigma methodology, SPC, and layered process audits (LPA), casting a digital management system to ensure casting repeatability. YBmetal tracks Cp/Cpk and yield metrics across batches to support continuous improvement.

Multi-Level Casting Inspection (Pre- and Post-Machining)

Casting Quality Inspection (Via Certified Foundries)

YBMETAL’s quality protocols govern all casting inspections, and results are cross-verified against incoming material checks before machining

Material Verification:

- Spectrometer analysis for chemical composition (e.g., C, Si, Mn, S, P, Cr, Mo, Ni, Cu)

- Tensile strength and hardness testing per ASTM/ISO standards

- Metallographic analysis for microstructure & nodularity (for ductile iron)

Dimensional Inspection:

- Manual and semi-automatic inspection tools

- CMM dimensional reports (as required for PPAP or FAI)

Surface & Visual Inspection:

- 100% visual inspection for casting defects: shrinkage, cracks, blowholes

- Surface roughness checks (Ra values per part spec)

NDT Capabilities (as requested):

- Magnetic Particle Inspection (MPI) for surface cracks

- Dye Penetrant Testing (DPT) for non-porous surface anomalies

- Radiographic testing (X-ray) for critical wall sections

Process & Traceability Control:

- Full batch traceability via unique lot numbers

- Control plans, FMEA, and production records

- Supplier certifications for ISO 9001 / IATF 16949

- Statistical Process Control (SPC) and 6 Sigma trial evaluation (on demand)

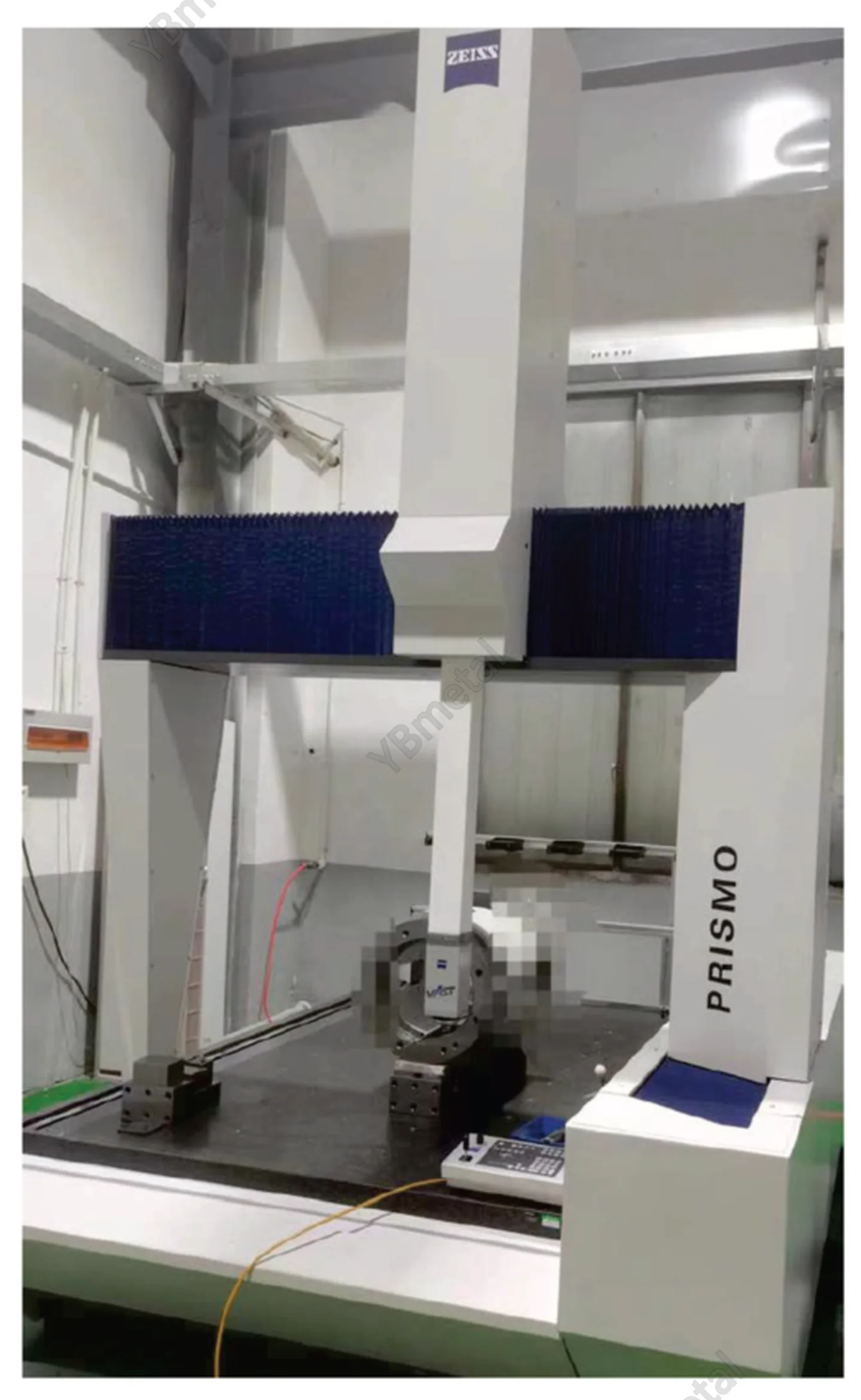

CNC Machining Inspection at YBMETAL Facility

Precision Measurement:

- Coordinate Measuring Machine (CMM): full 3D verification

- Height gauges, digital calipers, micrometers with 0.001 mm resolution

- Roundness and concentricity testers

Geometric Dimensioning & Tolerancing (GD&T):

- Position, flatness, runout, and profile inspections per drawing

- Sampling plans and 100% inspection for critical tolerances

Final Inspection & Certification:

- Inspection reports per PPAP/FAI standards (Level 3 or as required)

- Machining inspection sheets with operator sign-off

- SPC charts for high-volume repeat parts

Digital Documentation:

- CAD-to-CMM comparison

- Archivable inspection records with drawing reference

- Integration with MES/QMS for continuous improvement

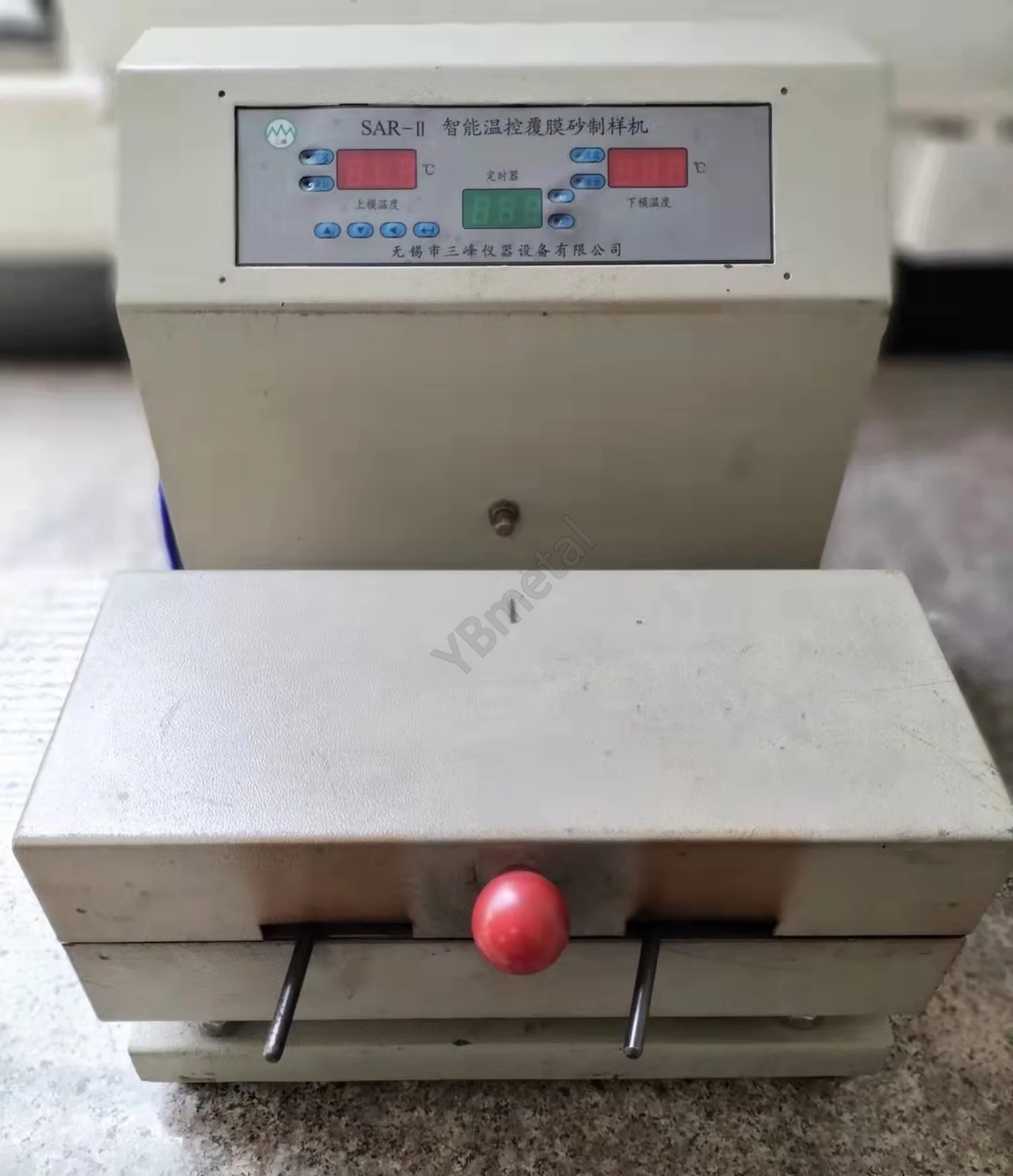

Casting Quality Inspection (Conducted via Certified Partners)

- OBLF Spark Spectrometer – chemical composition

- Emco / Tinius Olsen Brinell Hardness Testers

- Metallographic Microscope – matrix & graphite shape

- Ultrasonic Flaw Detector – internal porosity detection

- Surface Roughness Tester – as-cast Ra evaluation

- Magnetic Particle Testing (MT) – for crack inspection

- Customized templates – for basic dimensional checks

CNC Machining Inspection (In-house at YBMETAL)

- ZEISS CMM / Renishaw CMM – high-precision 3D measurement

- Height Gauges & Dial Indicators – secondary dimension control

- Surface Finish Tester – machined Ra measurements

- Go/No-Go Gauges – threads, shafts, bores

- Form & Concentricity Fixtures – runout and tolerance control

- Granite Surface Plates & Flatness Gauges

What Iron Casting Quality Control Includes with Every Delivery

- ✅ Material Certificates (EN10204 3.1 or 3.2)

- ✅ PPAP packages (Level 3)

- ✅ Dimensional Reports (CMM-based)

- ✅ Mechanical Test Reports (tensile, hardness)

- ✅ Surface Treatment Verification (coating, galvanizing, etc.)

- ✅ FAI report and process control documents (on request)

Why YBmetal for Iron Casting Quality Control?

- Certified Foundry Network: All castings sourced from ISO/IATF-approved suppliers

- Full Engineering Support: DFM + simulation to minimize scrap

- Integrated CNC Machining: One-stop casting-to-machining solution

- Global OEM Support: Documentation, packaging, and compliance for export-ready delivery

- Continuous Improvement: SPC, 6Sigma, and digital MES traceability

Ductile Iron Foundry China

Send Your Technical Drawing Today

YBMETAL supports global OEMs with zero-defect inspection systems and full-process documentation. From pilot batches to mass production, we help you meet quality goals with confidence.