Green Sand Casting Foundry in China – OEM Ductile & Gray Iron Parts

YBmetal are high-volume green sand casting supplier for OEMs seeking efficient, cost-effective production of ductile iron and gray iron parts. As a full-process casting supplier based in China with in-house CNC machining, we offer fast turnaround for green sand castings, fully machined and backed by international quality standards.

What Is Green Sand Casting?

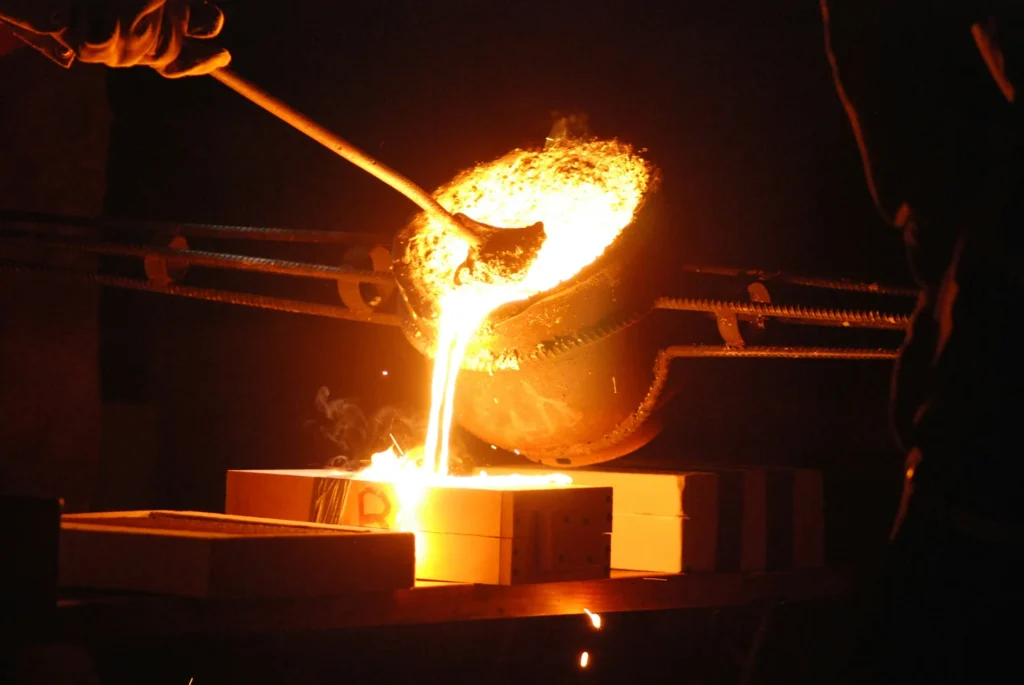

Green Sand Casting uses a mixture of natural sand, bentonite clay, water, and additives to form reusable molds for molten metal. Known for its cost-efficiency and adaptability, it is the most widely used process for ductile iron and gray iron casting production. Compared with resin sand or shell molding, green sand excels in low tooling cost and rapid cycle times, making it ideal for medium- to high-volume production with standardized part geometries.

Why Choose Green Sand Casting for Iron Parts?

YBMETAL partners with ISO-certified foundries equipped with full shell molding lines, including:

- ✅ Best for high-volume, low-cost iron castings: Green sand molds are quick to prepare and re-use, making this process ideal for mass production of iron components with stable dimensional tolerances.

- ✅ Excellent material compatibility: Supports both gray iron (HT200–HT300) and ductile iron (QT450–QT700, EN-GJS-500-7), suitable for industrial, agricultural, and commercial parts.

- ✅ Flexible mold sizes and core configurations: Capable of casting complex cavities and structural parts from 2 kg to 500 kg, using manual or automated molding lines.

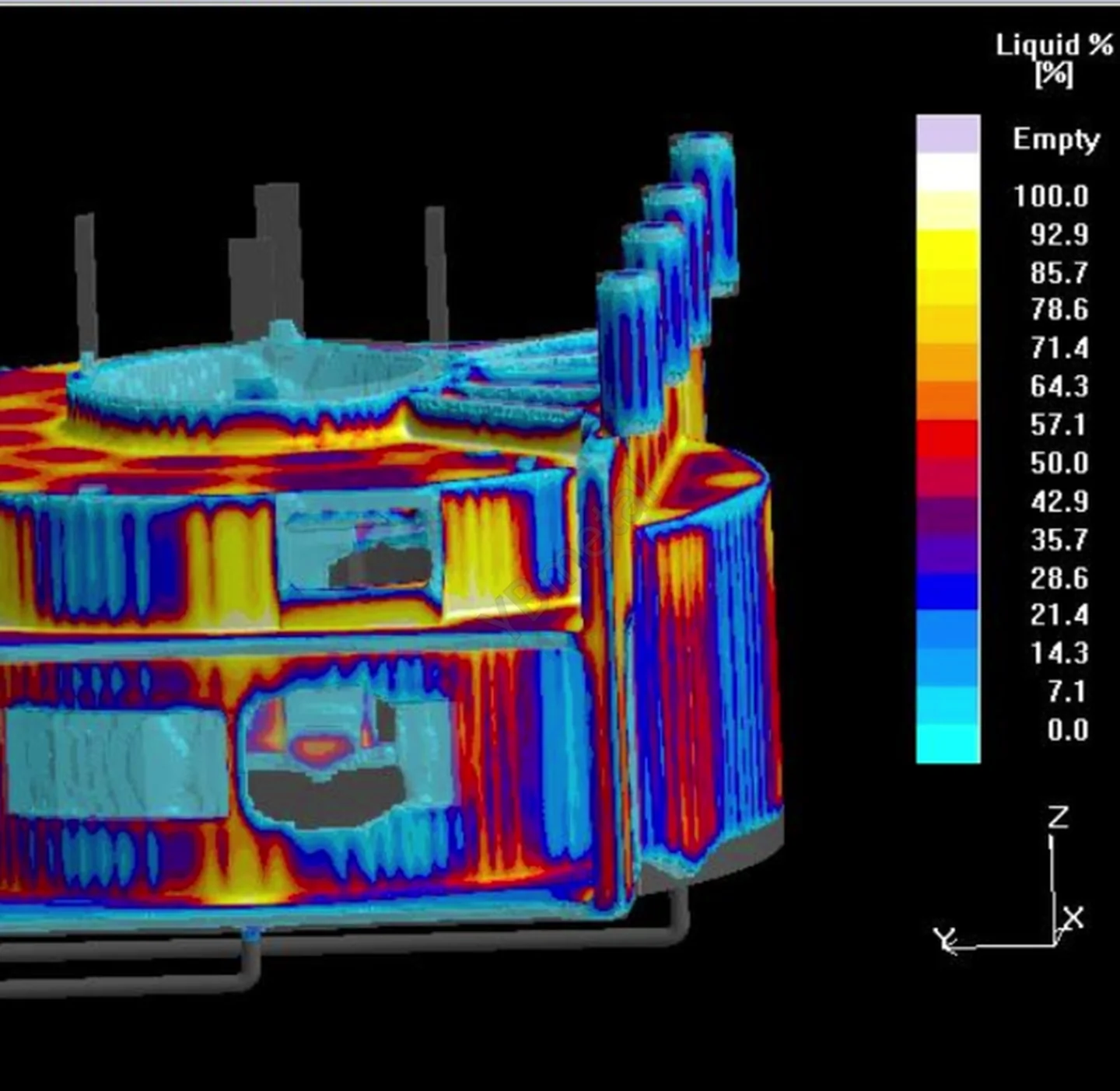

- ✅ Efficient solidification and cooling: The permeability of green sand allows controlled heat dissipation, reducing internal stress and improving the base mechanical properties.

- ✅ Eco-friendly and cost-efficient: Green sand can be reclaimed and recycled, minimizing waste and reducing production cost compared to resin or shell molding processes.

Our Capabilities in Green Sand Casting Iron Parts

- Mold weight range: 2 kg to 500 kg

- Casting materials: gray iron, ductile iron

- Molding methods: manual + automated green sand lines

- Optional cores and riser systems for complex internal shapes

- Integrated finishing, heat treatment, and CNC machining are available

- Full documentation: material certs, CMM reports, mechanical tests

Green Sand Cast Iron Applications

Green sand cast iron is widely used in OEM applications requiring cost-effective, medium- to high-volume production. Common parts include:

- Brake drums, flanges, and pump housings

- Gearbox covers and ductile iron brackets

- Agricultural components (drawbars, housings)

- Compressor bases and engine blocks

Ideal for automotive, agriculture, hydraulics, and general machinery, green sand casting supports gray and ductile iron parts with fast turnaround and stable dimensions.

Ductile Iron Foundry China

Request a Quote for Green Sand Castings Supplier: YBmetal

With decades of experience and a robust foundry network, YBMETAL ensures high-quality, competitively priced green sand iron castings delivered globally with consistent lead times and full technical support.