Austempered Ductile Iron castings (ADI) Supplier for High-Performance Iron Components in China

High-Performance ADI Castings for Strength, Toughness, and Wear Resistance

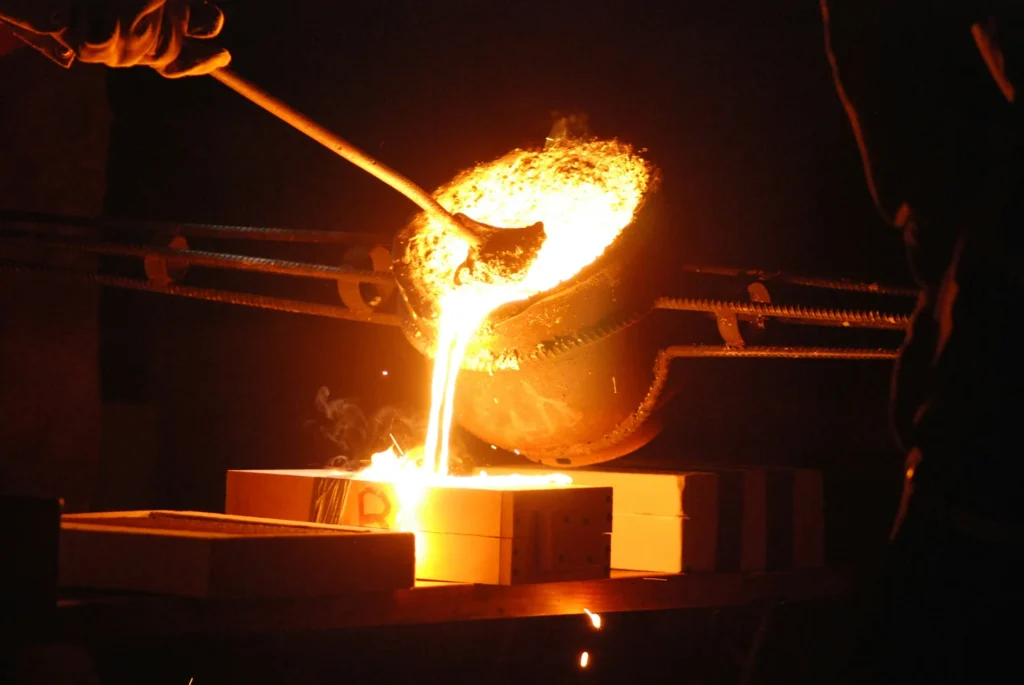

YBMETAL supplies custom Austempered Ductile Iron castings (ADI) for OEM applications requiring exceptional mechanical strength, toughness, and fatigue resistance. With advanced heat treatment control and precision CNC machining, we deliver fully finished ADI components tailored for demanding environments, including agriculture, mining, military, and high-load industrial use.

What are Austempered Ductile Iron Castings?

ADI (Austempered Ductile Iron Casting) is a special class of ductile iron that undergoes a controlled austenitizing and isothermal quenching process. The result is a unique ausferrite microstructure, combining the castability of iron with the strength and toughness often associated with steel.

This makes ADI ideal for components that need high wear resistance, impact strength, and lightweight design, without switching to forged or welded steel.

International Standards and Equivalent Grades of ADI

| Country / Standard | Equivalent Grade | Tensile Strength (MPa) | Elongation (%) | Notes |

|---|---|---|---|---|

| ISO (ISO 17804) | EN-GJS-800-10 | 800 | ≥10 | Highest elongation |

| EN-GJS-900-8 | 900 | ≥8 | Balanced grade | |

| EN-GJS-1050-6 | 1050 | ≥6 | Higher strength | |

| EN-GJS-1200-2 | 1200 | ≥2 | Structural usage | |

| EN-GJS-1400-1 | 1400 | ≥1 | Very high strength | |

| EN-GJS-1600-1 | 1600 | ≥1 | Maximum strength | |

| USA (ASTM A897) | Grade 1 (800-10) | 800 | ≥10 | Most ductile ADI |

| Grade 2 (900-8) | 900 | ≥8 | Common industrial use | |

| Grade 3 (1050-6) | 1050 | ≥6 | Gear-grade | |

| Grade 4 (1200-2) | 1200 | ≥2 | Powertrain-grade | |

| Grade 5 (1400-1) | 1400 | ≥1 | Structural high-load | |

| Grade 6 (1600-1) | 1600 | ≥1 | Max performance | |

| Germany (DIN/EN) | EN-GJS-800-10 to EN-GJS-1600-1 | Same as ISO 17804 | Used across EU | |

| Japan (JIS G5503) | No standardized ADI grades | – | – | Usually follows ISO |

| China (GB/T 34804) | ADI800-10, ADI900-8, etc. | Mirrors ISO/ASTM | Used in automotive, railway, and agri-machinery |

Why Choose Austempered Ductile Iron Castings?

- ✅ Strength-to-weight advantage: ADI can reach tensile strengths up to 1600 MPa with excellent elongation, outperforming many steels at a lower weight.

- ✅ Superior wear & fatigue resistance: The ausferritic structure resists surface wear and cyclic stress — ideal for rotating or impact-loaded components.

- ✅ Lower cost than steel or forging: ADI parts are cast like ductile iron, avoiding costly steel forging or machining from billet.

- ✅ Excellent machinability after austempering: With optimized microstructure and CNC support, post-treatment machining remains accurate and efficient.

- ✅ Design flexibility: ADI enables near-net-shape casting with integrated geometry, simplifying complex welded assemblies.

Limitations of ADI Castings

- ❌ Higher production complexity: ADI requires precise heat treatment (austenitizing and austempering) with tight process control. This increases cost, lead time, and demands specialized foundry expertise.

- ❌ Limited weldability: Like other ductile irons, ADI is not readily weldable due to its hardened microstructure; welding can cause cracking or loss of mechanical properties.

- ❌ Sensitive to section thickness: Thick sections may not fully transform into the desired ausferritic structure, leading to inconsistent hardness or reduced impact strength.

- ❌ Not suitable for high-temperature environments: ADI loses mechanical properties above ~300 °C (572 °F), making it unsuitable for continuous high-heat applications such as exhaust manifolds or furnace parts.

- ❌ Higher initial tooling & process cost: Compared with standard ductile iron, ADI castings involve more tooling precision, longer cycle times, and post-cast treatments, impacting cost-effectiveness for low-volume runs.

Typical Applications of ADI Castings

- Wear parts for agricultural & construction machinery (plows, rollers, arms)

- High-load automotive components (suspension, gears, differential carriers)

- Mining and defense applications requiring extreme durability

- Replacing steel forgings with cast equivalents

- Custom castings with fatigue-critical surfaces

Our ADI Castings & Machining Capabilities

- Material: Ductile iron QT600–QT700 base

- Heat treatment: Austempering furnace, controlled cycles

- Weight range: 5 kg to 300 kg

- Post-treatment CNC machining: milling, boring, drilling

- Quality checks: hardness, microstructure, tensile, fatigue

- Documentation: Material certs, PPAP, CMM, FAI, dimensional reports

Trusted ADI castings Manufacturer in China

YBMETAL works with ISO 9001 / IATF 16949 certified heat treatment partners and manages end-to-end production — from tooling design to final CNC-finished ADI components.