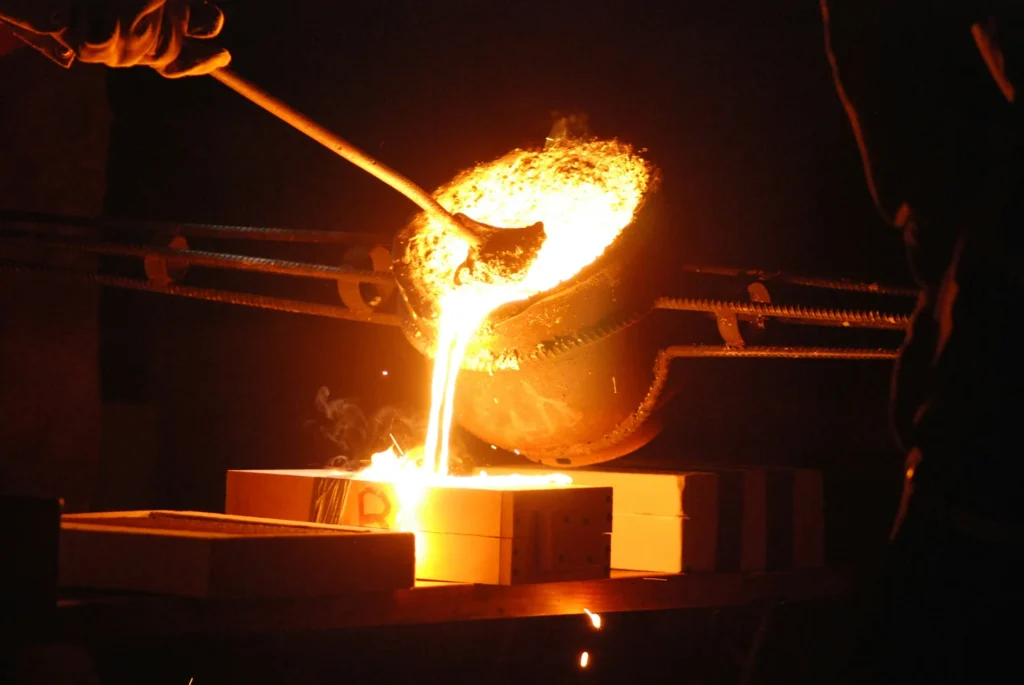

Iron Casting Methods for OEM Parts – Choose the Right Process with YBmetal

Choosing the right iron casting methods is critical for performance, cost, and lead time. At YBMETAL, we don’t just offer Green Sand Casting, Resin Sand Casting, and Shell Molding Iron Casting; we help you evaluate your part and select the optimal iron casting process based on its weight, geometry, functional needs, and volume. As an engineering-led China casting supplier with in-house CNC machining and ISO-certified foundry partners, YBMETAL ensures each OEM part follows the most efficient, cost-effective, and quality-assured production route.

Why Choosing the Right Iron Casting Method Matters

Not all parts are created equal, and not all casting methods perform the same. Based on your drawing, tolerances, surface finish, and post-processing requirements, our engineers recommend the best-fit process to avoid over- or under-engineering. You don’t need to decide up front — just send us your part, and we’ll guide you.

Overview of Common Iron Casting Methods

- Best for: High-volume, low-cost production

- ✅ Material: Gray Iron (HT200–HT300), Ductile Iron (QT450–QT700)

- ✅ Size range: 2–500 kg

- Most economical for medium-to-large batches

- Short lead time and low tooling cost

- Suitable for brackets, flanges, and pump housings

- ✅ Best for: Large, complex, heavy-duty parts

- ✅ Material: Gray Iron, Ductile Iron, Cast Steel

- ✅ Size range: 5–8000 kg

- High mold strength and tighter tolerances

- Ideal for gearboxes, machine bases, and valve bodies

- Supports pressure testing, heat treatment, and CNC

- ✅ Best for: Precision parts with fine features

- ✅ Material: Gray Iron, Ductile Iron

- ✅ Size range: 0.5–80 kg

- Superior surface finish and dimensional repeatability

- Excellent for valve bodies, exhaust manifolds, and support brackets

- Perfect fit for tight-machining downstream

Casting Process Comparison Table

| Feature / Method | Green Sand | Resin Sand | Shell Molding |

|---|---|---|---|

| Best for | High volume | Large complex | Precision parts |

| Weight range | 2–500 kg | 5–8000 kg | 0.5–80 kg |

| Surface finish | Moderate | Good | Excellent |

| Machining allowance | Higher | Moderate | Low |

| Tooling cost | Low | Medium | High |

| Core complexity | Moderate | Complex cores | Limited |

| Typical parts | Flanges, pipes | Bases, housing | Valves, brackets |

Ductile Iron Foundry China

Let YBMETAL Guide Your Casting Process

You don’t need to decide the casting method alone. We’ll:

- Review your 2D/3D drawing, specs, and functional needs

- Recommend the most suitable casting process

- Provide a fast proposal with lead time, cost, and DFM suggestions

- Deliver quality-controlled, fully machined parts — ready to assemble