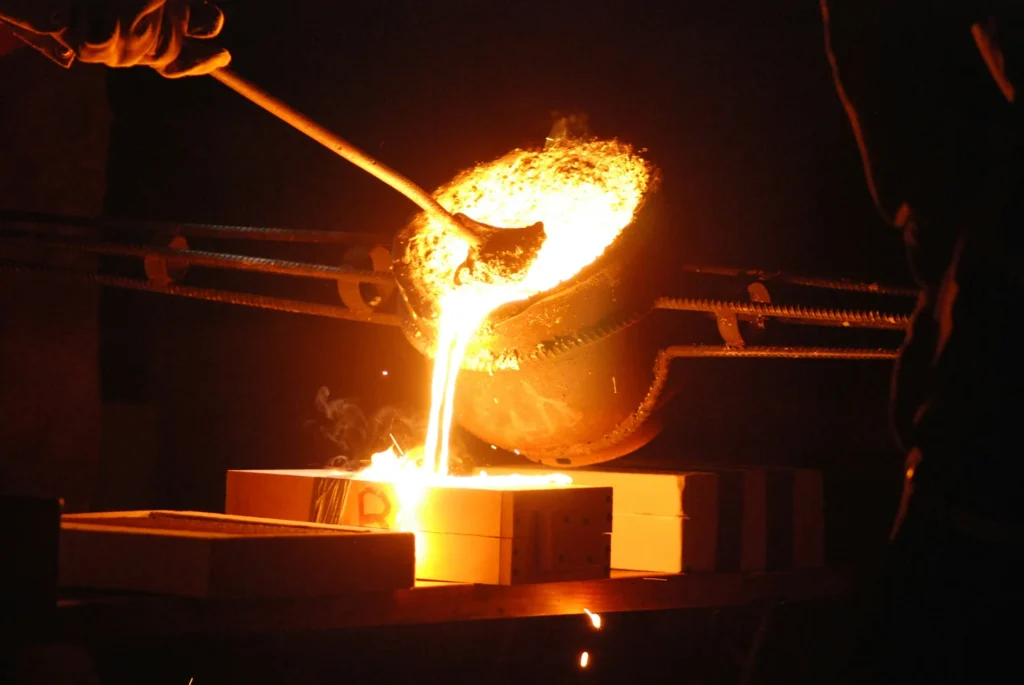

Precision CNC Machining for Castings, Iron & Ductile & ADI Components

YBmetal delivers high-precision CNC Machining for Castings services tailored for iron castings — including gray iron, ductile iron, and ADI components. With an in-house CNC workshop and a certified foundry network, we offer an integrated casting-to-machining solution for OEMs in the industrial, transportation, and energy sectors.

Integrated Casting + CNC Machining Workflow

Our hybrid model allows us to control both casting quality and final machining dimensions, ensuring every component meets engineering tolerances and documentation requirements.

- ✅ ISO/IATF-certified foundry sourcing

- ✅ CNC turning, milling, boring, gear hobbing

- ✅ CMM inspection, PPAP, and dimensional reports

- ✅ Flexible batch size and lead time

- ✅ Serving global OEMs in automotive, agriculture, and industrial machinery

CNC Machining for Castings Capabilities at YBMETAL

We operate 60+ precision machines and offer full-spectrum services from rough machining to final surface finishing.

| Capability | Details |

|---|---|

| Machining Materials | Gray Iron, Ductile Iron, ADI, Cast Steel |

| Equipment Types | CNC lathes, 3/4-axis VMCs, boring machines, gear hobbing |

| Inspection Tools | Renishaw CMM, GD&T, surface roughness tester |

| Documentation | PPAP, FAI, CMM reports, material certs |

| Production Range | From small prototypes to mid-volume series |

Core Equipment Lineup (selected from 30+ machines):

| Equipment Type | Model / Range | Qty |

|---|---|---|

| Horizontal CNC Lathes | CAK6140 / CAK6150 (Φ400–450 × 1000 mm) | 18 |

| Vertical Machining Centers (3-axis) | VCM850 / VCM1160 / BFC-650 | 16 |

| 4-axis Machining Center | VMC850 | 3 |

| Large Machining Center | VCM2500 / DHX3022 (up to 3 m × 2 m) | 3 |

| Boring Machines | Z3050, T6213 (heavy-duty vertical boring) | 3 |

| Gear Machining | Y3150/3 (gear hobbing machines) | 4 |

| Milling & Drilling | ZK5125-JH / XKA5032 / TK7150 | 8 |

| Double-Spindle CNC Turning | CK46-4+Y, STAR CNC SB-20R | 3 |

| Surface Grinders / Grinders | CW6110E / CW61160 / C61200 | 2 |

| Press & Forming Equipment | Hydraulic Press, CNC Shear & Benders | 10+ |

Why Choose YBMETAL for CNC Machining for Castings:

| Advantage | Description |

|---|---|

| One-Stop Solution | From casting to final machining, all under coordinated QC. |

| Advanced Accuracy | Tolerances up to ±0.01 mm; CMM & digital traceability. |

| Material Expertise | Specialists in ductile iron, ADI, and high-hardness cast steel. |

| OEM-Ready Documentation | Full PPAP, FMEA, and surface finish certification available. |

| Global Delivery | Seaworthy packaging and export support for international buyers. |

We handle final tolerancing, assembly-fit readiness, and full inspection documentation.

YBmetal’s in-house machining capability is backed by:

Global references and export track record, Trusted CNC Machining Partner in China:

- YBMETAL’s in-house machining capability is backed by:

- Engineering team with 10+ years in iron casting machining

- ISO 9001:2015 and IATF 16949 compliant systems

- Process control from CAD model to final QC

- Global references and export track record

Ductile Iron Foundry China

- How to Choose a Gray Iron Casting Supplier/Exporter

- Gray cast iron: The Essential Guide to Grades & Uses

- ASTM A48 Class 35 Castings: Properties, Tolerances & Best Uses

- How to Choose Austempered Ductile Iron Grades (ADI 1050)

- ADI Casting Process: From Heat Treatment to Performance

Trusted Ductile Iron Foundry in China

We’ll review tolerances, casting specs, and machining feasibility, and deliver parts that are ready for assembly.