About YBmetal – Trusted China Iron Casting Supplier with CNC Machining Expertise

YBMETAL is a China Iron Casting Supplier with in-house machining roots, connecting international OEMs with high-quality gray iron, ductile iron, ADI, and cast steel components. Headquartered in Suzhou, we specialize in engineering-led casting solutions with full machining, inspection, and export capabilities. Our team supports communication in English, Chinese, and Spanish, ensuring seamless project coordination across technical, quality, and logistics stages.

Our History: From CNC Machining Workshop to Iron Casting Partner in China

Our roots date back to 1991, when our parent company, FUSHUN, began as a precision CNC machining workshop serving industrial clients in China. Over the decades, we became the go-to machining partner for Chinese foundries. This allows us to deliver castings that are not only sourced and inspected but also CNC-machined and finished under our own control.

To meet global demand for turnkey casting solutions, we founded YBmetal — combining our in-house machining capacity with a verified network of ISO-certified foundries.

Solving China Iron Casting Sourcing Problems: Quality, Lead Time & Communication

Sourcing iron castings from China often brings challenges: inconsistent quality, delayed lead times, unclear specs, and poor communication.

- ISO 9001 / IATF 16949 certified foundries and PPAP-ready iron casting parts

- In-house CNC machining for full process control and batch traceability

- Engineers fluent in English, Chinese, and Spanish for smooth technical coordination

- Reliable lead times and fast sampling for custom ductile iron and gray iron components

- Design for manufacturability (DFM) support to reduce cost and complexity

As a China-based iron casting and CNC machining supplier, we help OEMs worldwide reduce sourcing risk and improve project efficiency.

Why Global OEMs Choose YBMETAL – China Iron Casting Partner

Sourcing iron castings from China often brings challenges: inconsistent quality, delayed lead times, unclear specs, and poor communication.

- ✅ In-house CNC machining for iron castings

- ✅ Engineering-led sourcing and design optimization

- ✅ RFQ + CAD review, PPAP, and full documentation

- ✅ Access to verified ISO 9001 / IATF 16949 foundries

- ✅ Multi-language support (English / 中文 / Español)

- ✅ One-stop coordination from sampling to delivery

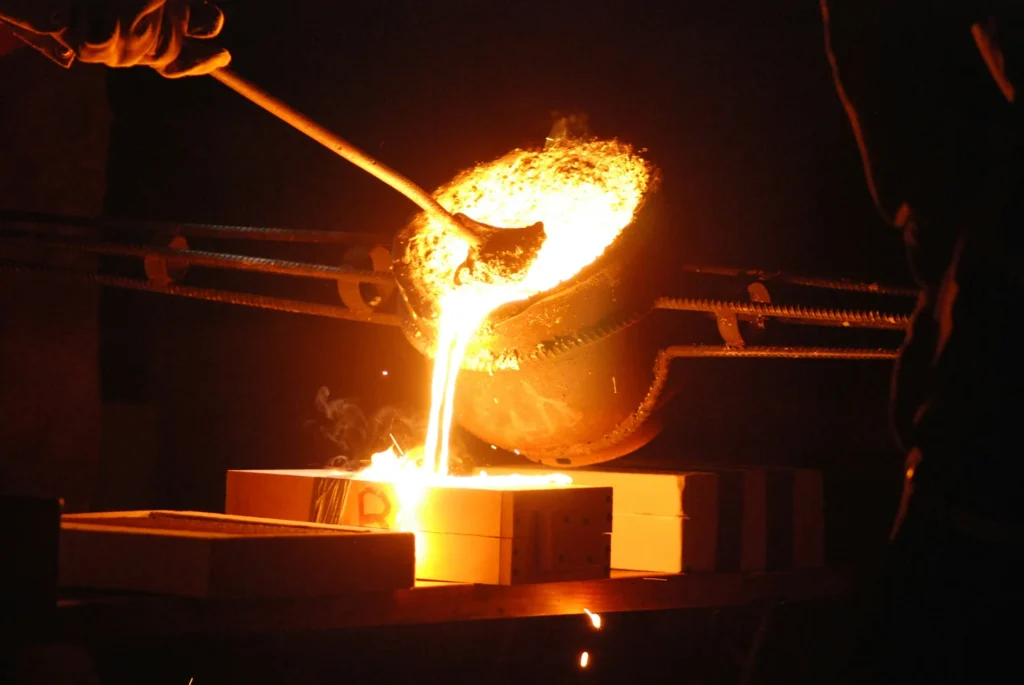

Iron Casting Capabilities: Gray Iron, Ductile Iron & ADI Supply

We deliver high-quality components using:

- Green sand casting, resin sand casting, shell molding, lost wax (investment casting)

- Materials: HT200–HT300, QT450–QT700, EN-GJS-500-7, ADI, cast steel (ZG230–450)

- Sizes: from 2 kg to 8000 kg

Regularly supplied parts include:

- Ductile iron seeding knife point

- Cradle bracket of the cylinder

- Cast iron exhaust manifold

- Pump body and valve housing

- Tractor gearbox housings

- Pipe fittings, flanges, and manhole covers

CNC Machining for Cast Iron Parts: In-House Post-Processing

YBMETAL operates a fully equipped CNC machining workshop in Suzhou, China, providing tight-tolerance, OEM-grade machining for ductile iron, gray iron, and cast steel castings. Our in-house facility gives us full control over quality, cost, and lead times for custom iron casting components.

Machine Fleet (18+ units):

- CNC lathes CAK6140 / CAK6150 — Ø400–450 mm × 1000 mm

- 3- & 4-axis machining centers VCM1160 / VCM850 — up to 1000 × 600 mm

- Boring machines TK7150 / T6213 — for parts up to 2.5 meters

- Supported by precision tapping, drilling, and grinding

Process:

- CNC turning, vertical & horizontal milling (VMC / HMC)

- Surface finishing: painting, powder coating, blackening, galvanizing

- Heat treatment: annealing, normalizing, quenching, tempering

This integrated production line enables us to deliver PPAP-traceable machined castings, ready for global OEM assembly lines.

Full Quality Control for Iron Castings: ISO Inspection & Batch Traceability

YBMETAL applies strict quality control to every project, covering both our in-house CNC machining inspection and supplier-managed casting verification:

- Dimensional checks for machined parts: CMM, 3D scanning, precision gauges

- Machining quality control: surface finish, thread verification, and tolerance validation

- Casting analysis via partner foundries: spectrometer, C–S analyzer, tensile, impact, hardness tests

- Metallography & NDT (UT / MT / RT) available through certified suppliers or third-party labs

- Batch-level traceability: tied to operator, tooling, casting lot, and machining batch

- Full documentation: material certificates, dimension reports, FAI, PPAP upon request

All inspections meet ISO 9001 / IATF 16949 standards. The result: OEM-grade iron castings with validated machining accuracy and reliable process traceability.

Project Management from DFM to Delivery: Sourcing + Machining Control

All parts undergo full-process quality control, including:

- Technical review: drawing + CAD support

- Mold flow simulation and tooling guidance

- Sampling and verification

- Real-time project tracking

- Export packing and bilingual documentation

Case Studies: CNC Machined Iron Castings Delivered to Global OEMs

BMETAL supplies custom gray iron, ductile iron, and cast steel castings, fully CNC machined and export-ready, for OEMs worldwide.

- Agricultural OEM – Europe: QT600-3 gearbox housing, 80 kg→ DFM cut machining time by 25%

- Pump Manufacturer – USA: EN-GJS-500-7 valve body → 4-week lead time, passed CMM & pressure test

- Vehicle Supplier – Germany: HT250 exhaust manifold → ISO 9001 foundries, PPAP + full traceability

These delivered cases show our capabilities in iron casting sourcing, CNC machining, and OEM part delivery with full documentation.

- ✅ All parts include CNC machining, PPAP docs, CMM reports, and material certs

✅ Expertise in machined iron castings, OEM-grade ductile iron parts, and casting sourcing from China

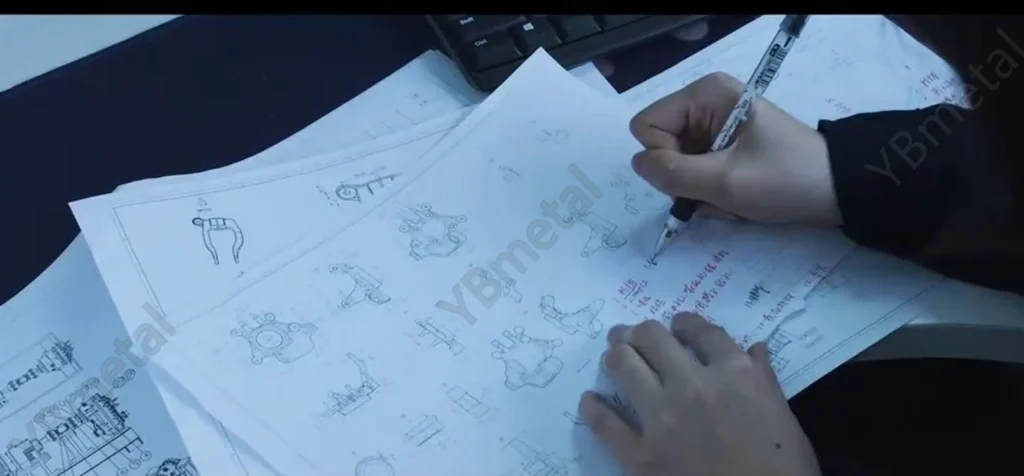

DFM & Engineering Support for Optimized Iron Casting Production

We help optimize part design before tooling to ensure smooth iron casting and CNC machining:

- Detect undercuts, thin walls, and poor draft angles

- Improve machining allowance, core & mold design

- Review tolerances, threads, and critical surfaces

These DFM actions are supported by our deep experience in iron casting, CNC machining, and collaboration with ISO 9001 / IATF 16949 certified foundries:

- ✅ Support for gray iron (HT200–HT300), ductile iron (QT450–QT700 / EN-GJS-500-7), and cast steel (ZG230–450)

- ✅ Engineers fluent in English / 中文 / Español

- ✅ Backed by ISO-certified foundries and our own CNC machining shop

Trusted by global OEMs for precision cast + machined components from China — from design review to final delivery.

Ductile Iron Foundry in China

- How to Choose a Gray Iron Casting Supplier/Exporter

- Gray cast iron: The Essential Guide to Grades & Uses

- ASTM A48 Class 35 Castings: Properties, Tolerances & Best Uses

- How to Choose Austempered Ductile Iron Grades (ADI 1050)

- ADI Casting Process: From Heat Treatment to Performance

Ready to Start Your Iron Casting Project?

Send us your drawings or part photos, and we’ll prepare a tailored sourcing plan, including foundry recommendations, a cost estimate, and a sampling lead time.