Iron Casting Foundry Network in China for Ductile & Gray Iron & ADI Components

Scalable Iron Casting Foundry Network in China

YBMETAL is a trusted iron casting foundry sourcing partner based in China, offering engineered gray and ductile iron castings for industrial, municipal, and automotive sectors. Through our ISO/IATF-certified foundry network and in-house CNC machining support, we provide reliable, scalable, and fully traceable iron casting solutions for OEMs and Tier 1 suppliers worldwide.

Partner Foundry Capabilities for Iron Casting

| Category | Capability Details |

|---|---|

| Casting Materials | Gray Iron (HT150–HT300), Ductile Iron (QT400–QT800), ADI (Austempered Ductile Iron) |

| Processes | Green sand molding, resin sand casting, shell molding, lost foam |

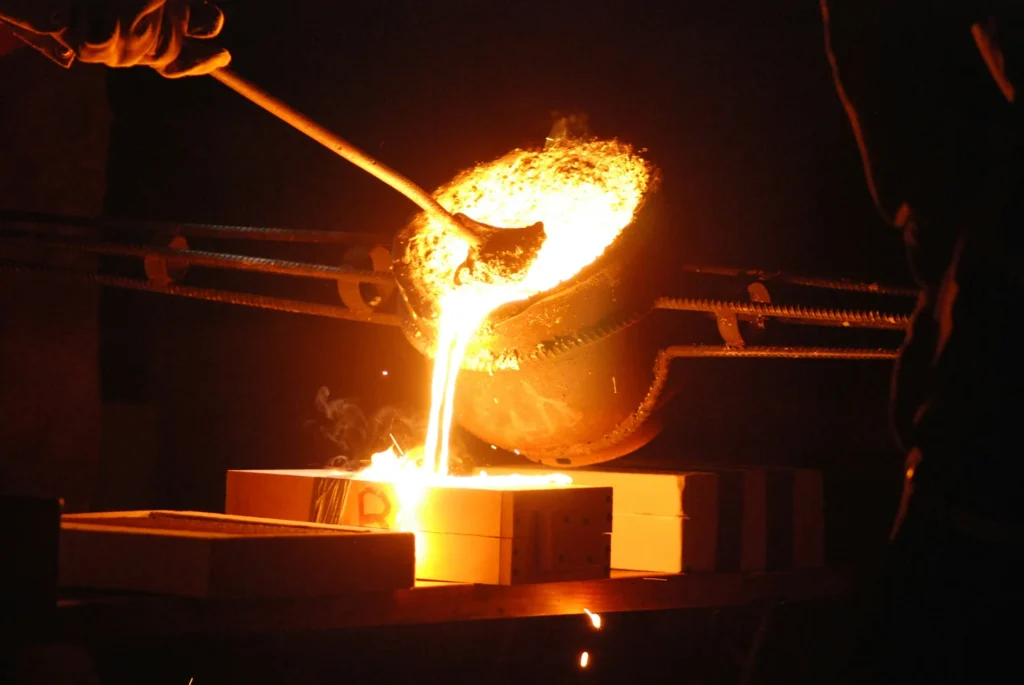

| Pouring Capacity | Up to 10 tons per casting; batch pouring for small and mid-size components |

| Melting Equipment | Medium-frequency electric induction furnaces: 0.5T, 1T, 1.5T, 3T units |

| Annual Capacity | 40,000–60,000 tons of iron castings |

| Machining Readiness | As-cast, semi-machined, or full CNC finish (via YBMETAL in-house machining center) |

| Heat Treatment | Normalizing, annealing, quenching & tempering, austempering (for ADI) |

| Typical Parts | Housings, flywheel shells, arms, brackets, yokes, transmission cases, hubs |

| Casting Size Range | From <5 kg to 1000+ kg parts; wall thickness control from 5 mm to 100 mm |

| Tolerances | As per ISO 8062-3 CT8–CT11 (can improve via machining) |

All components are finished under strict standards for iron casting foundries serving global OEMs.

Why Global OEMs Choose YBmetal as Their Iron Casting Foundry

| Benefit | Description |

|---|---|

| Certified Iron Casting Foundry Network | We work with ISO 9001 / IATF 16949 certified foundries to ensure compliance, consistency, and accountability. |

| Engineering-Based Casting Support | From 2D/3D drawing reviews to solidification simulation, we reduce risk and improve first-pass yield. |

| Full Material Testing & Traceability | Tensile tests, CMM reports, metallurgical analysis, PPAP, FMEA – all available on request. |

| Flexible Production Capability | We handle prototyping and small to medium batch production with stable lead time and dimensional control. |

| In-House Machining Integration | Castings are CNC-machined at our own facility for faster delivery and tighter tolerances. |

With over 12 years of experience serving industrial OEMs across Europe and North America, we ensure casting accuracy, process transparency, and global delivery support.

Applications of Our Iron Casting Foundry Services

We supply custom iron castings for various industries:

- Machine Tool Castings: Lathe beds, column blocks, base frames

- Automotive & Truck Components: Brake drums, axle housings, suspension brackets

- Agricultural Castings: Gearbox housings, tiller arms, trailer parts

- Municipal Iron Castings: Manhole covers, trench grates, valve boxes

- Pump & Valve Bodies: Crankcases, impellers, pump shells

- Heavy Equipment Castings: Transmission cases, hubs, torque housings

We handle final tolerancing, assembly-fit readiness, and full inspection documentation.

Iron Casting Foundry with Proven Quality Control

Strict QC measures back every project at YBmetal:

- Mold design & DFM review before tooling

- Material composition test + microstructure validation

- Dimensional accuracy with CMM & 3D scanning

- Documentation: PPAP, FMEA, ISO certs, raw material certs

- Full traceability from casting to final machining

We handle final tolerancing, assembly-fit readiness, and full inspection documentation.

Ductile Iron Foundry China

- How to Choose a Gray Iron Casting Supplier/Exporter

- Gray cast iron: The Essential Guide to Grades & Uses

- ASTM A48 Class 35 Castings: Properties, Tolerances & Best Uses

- How to Choose Austempered Ductile Iron Grades (ADI 1050)

- ADI Casting Process: From Heat Treatment to Performance

Start Your Project with a Reliable Iron Casting Foundry

Whether you’re sourcing ductile iron castings( ADI) for power equipment or gray iron housings for automation systems, YBMETAL offers:

- Rapid prototyping & tooling setup

- Consistent casting + CNC machining integration

- Compliance with ISO / ASTM / EN standards

- Global delivery & export coordination