Iron Casting Materials Guide – Gray, Ductile, ADI & Cast Steel Comparison

Choose the Right Material for Your OEM Casting Project

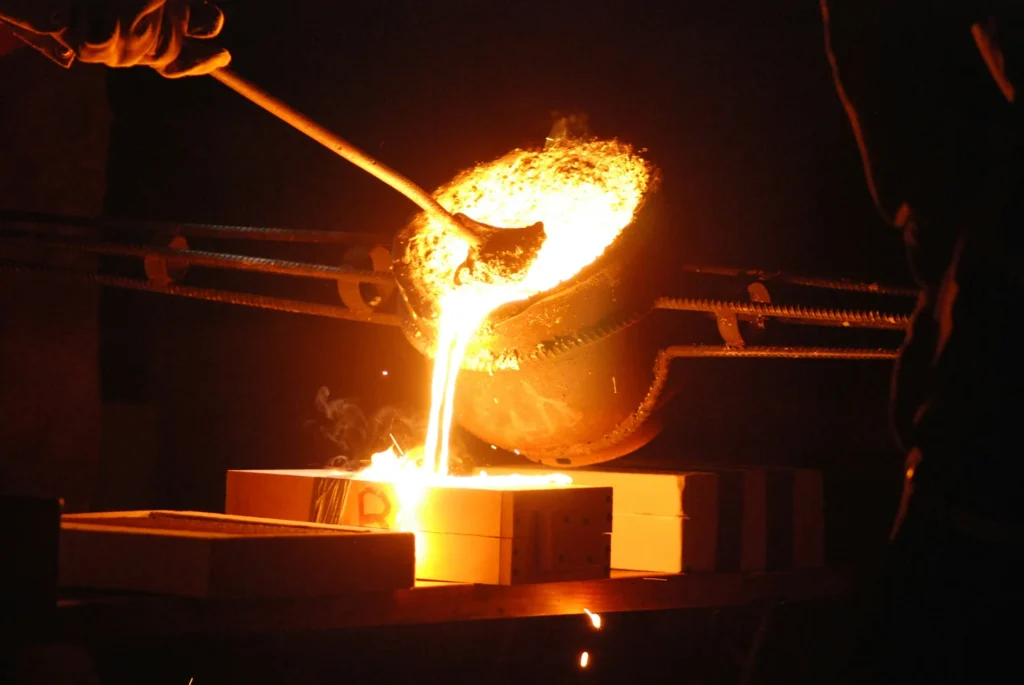

At YBMETAL, we specialize in producing high-performance Iron Casting Materials: gray iron, ductile iron, and cast steel components with precision CNC machining. This page helps you compare their technical properties, cost-effectiveness, and application suitability — so you can choose the ideal casting material for your design.

Why Material Choice Matters in Casting

Each casting material has distinct mechanical and performance traits. Selecting the wrong metal can lead to cracking, premature wear, or overengineering. YBMETAL offers expert guidance to help you balance cost, performance, and manufacturability from the start.

Casting Methods

Best for parts where cost-efficiency, damping, and machinability are top priorities. Not suitable for impact or pressure.

- ✅ Excellent for: brake drums, housings, flanges, exhaust manifolds

- ✅ Not suitable for: dynamic loads, weld repairs, pressurized systems

Best for components needing high strength, moderate pressure resistance, and some ductility, without the cost of steel.

- ✅ Excellent for: gearbox housings, suspension arms, valve bodies

- ✅ Not suitable for: high-impact or welded structures

Best for components requiring an exceptional strength-to-weight ratio, wear resistance, and fatigue performance, while still benefiting from lower cost and castability compared to steel.

- ✅ Excellent for: gears, crankshafts, heavy-duty brackets, off-road components, agricultural machinery

- ✅ Not suitable for: parts requiring welding, components under extremely high or shock loading without further treatment

Best for impact-prone, welded, or high-stress parts. Offers excellent mechanical strength and post-processing options.

- ✅ Excellent for: mining equipment, frames, couplers, pressure valves

- ✅ Not suitable for: low-cost, high-volume parts

Comparison of Gray Iron, Ductile Iron, ADI, and Cast Steel

| Property | ADI | Gray Iron | Ductile Iron | Cast Steel |

|---|---|---|---|---|

| Strength | Very high | Low–moderate | High | Very high |

| Ductility | Good–Excellent (depends on grade) | Brittle | Excellent | Excellent |

| Impact Resistance | Excellent | Poor | Good | Excellent |

| Vibration Damping | Moderate | Excellent | Moderate | Low |

| Machinability | Moderate (harder than ductile) | Excellent | Good | Moderate |

| Pressure Tightness | Good | Poor (porous) | Moderate | Excellent |

| Weldability | Not weldable (due to heat treatment) | Not weldable | Limited | Fully weldable |

| Weight Range | 5–500 kg | 2–500 kg | 5–8,000 kg | 5–3,000 kg |

| Typical Use | Gears, brackets, axles, and agricultural parts | Static housings, covers | Load-bearing, automotive | High-load, impact components |

| Cost | Moderate–High | Low | Moderate | High |

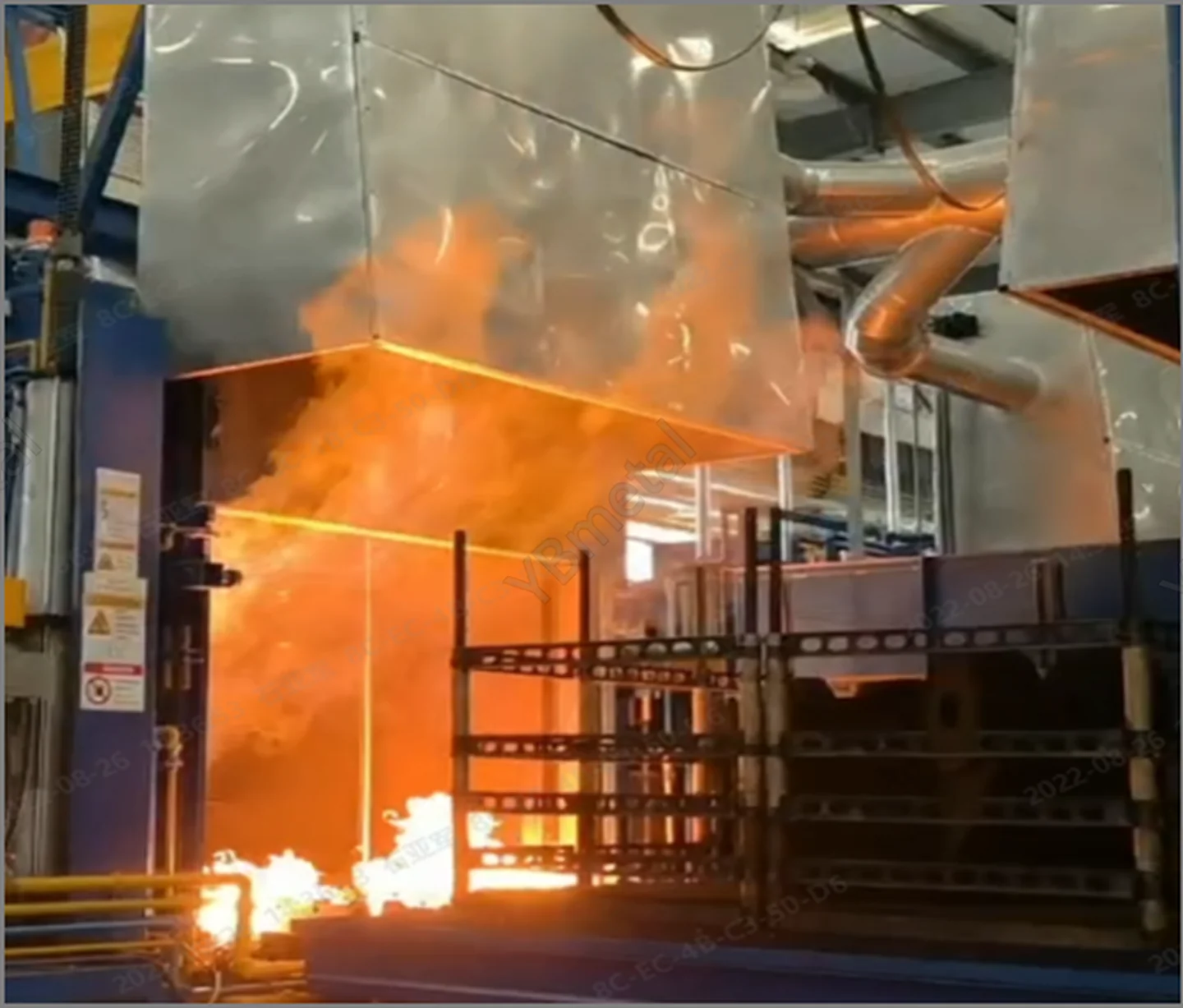

Ductile Iron Foundry China

YBMETAL Material Consultation

Not sure which material is right for your casting project? YBMETAL offers Iron Casting Materials:

- Engineering support & DFM

- Mechanical requirement review

- Heat treatment and machining considerations

- Certification and compliance (PPAP, CMM, material certs)