Resin Sand Casting in China – OEM Gray Iron, Ductile Iron & Cast Steel Parts

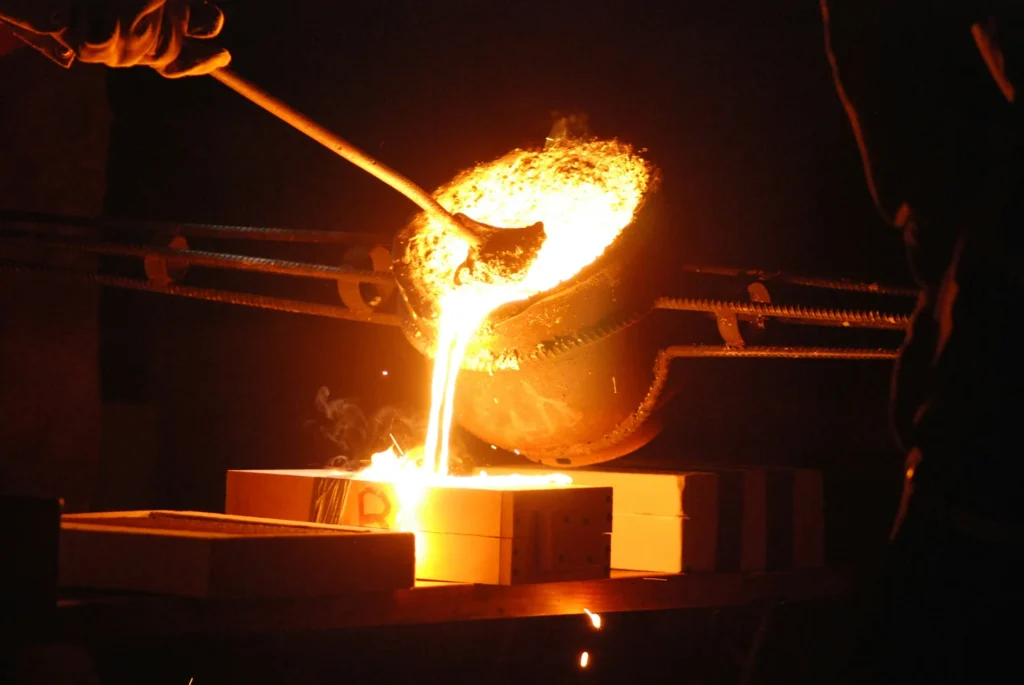

YBMETAL offers Resin Sand Casting (furan resin casting) for producing large, high-strength gray iron, ductile iron, and cast steel parts. This chemically bonded sand process ensures superior mold strength, surface finish, and dimensional accuracy—ideal for structural, pressure-bearing, and CNC-machined components. As a full-service China casting supplier with in-house CNC machining, we deliver OEM-grade resin sand castings, fully machined, inspected, and export-ready with PPAP and CMM reports.

What Is Resin Sand Casting?

Also called furan resin sand casting, this process uses chemically bonded sand molds to produce large, complex iron and steel components. Compared with green sand or shell molding, resin sand offers superior mold strength, surface finish, and dimensional stability, making it ideal for heavy-duty or structurally demanding parts.

Why Choose Resin Sand Casting for Your Iron Components?

- ✅ Suitable for large and heavy parts: High mold rigidity allows casting of iron and steel parts up to 8 tons — perfect for pump housings, machine beds, and gearboxes.

- ✅ Improved surface quality & tighter tolerances: Compared to green sand, resin molds reduce casting defects and machining allowance, saving post-processing time.

- ✅ Excellent for complex internal cavities: Custom resin cores enable high-precision oil galleries, duct channels, and thick-walled structures.

- ✅ Reliable cooling and heat treatment: Even solidification helps reduce stress and ensures dimensional consistency after post-cast heat treatment.

- ✅ Material flexibility: Supports gray iron (HT200–HT300), ductile iron (QT450–QT700, EN-GJS-500-7), and cast steel (ZG230–450).

Our Casting Capabilities

- Mold core production with furan / alkaline-phenolic resin sand

- Manual & semi-automatic molding lines

- Casting weights: 5 kg to 8,000 kg

- Custom tooling and mold flow simulation

- Optional surface treatments and post-casting machining

All castings are backed by full-process traceability and quality control reports, including chemical composition, CMM dimensions, mechanical properties, and optional third-party inspection.

Ductile Iron Foundry China

Request a Quote for Resin Sand Casting Services

We’ll evaluate your part and provide a resin sand casting proposal