Shell Molding Iron Casting Foundry in China – Precision Gray & Ductile Iron Castings

YBmetal offers high-precision gray iron and ductile iron castings using the shell molding iron castings method, also known as hot shell and core casting or pre-coated resin sand casting. This process delivers consistent casting quality, excellent surface finish, and high dimensional accuracy—ideal for complex and machined iron components.

What is Shell Molding Casting?

Shell molding uses pre-coated resin sand heated in a metal pattern to form rigid sand shells. This creates precise molds that are stronger and more accurate than green sand or furan sand.

- Casting metals: Gray iron (HT200–HT300), ductile iron (QT450–QT700, EN-GJS-500-7)

- Typical wall thickness: ≥ 4 mm

- Surface roughness: Ra 6.3–12.5 μm

- Tolerance grade: CT7–CT8

- Batch suitability: Medium to high volume production

This process is ideal for parts requiring machining, dimensional consistency, or detailed features like internal cores.

Why Choose Shell Molding for Iron Castings?

Shell molding casting offers critical benefits for OEM-grade parts:

- ✅ Tight tolerances — Ideal for precision iron castings with critical dimensions

- ✅ Clean surface finish — Minimizes machining needs

- ✅ Repeatable quality — Supports stable, scalable iron casting production

- ✅ Reduced internal defects — Compared to green sand or resin sand processes

- ✅ Compatible with CNC machining — Smooths the path for post-casting operations

- ✅ Better dimensional control — Especially on thin-walled, cored, or detailed parts

This process is preferred for castings used in pumps, valves, housings, manifolds, flanges, and other OEM parts that demand machining and documentation.

Our Shell Molding Iron Castings Capabilities

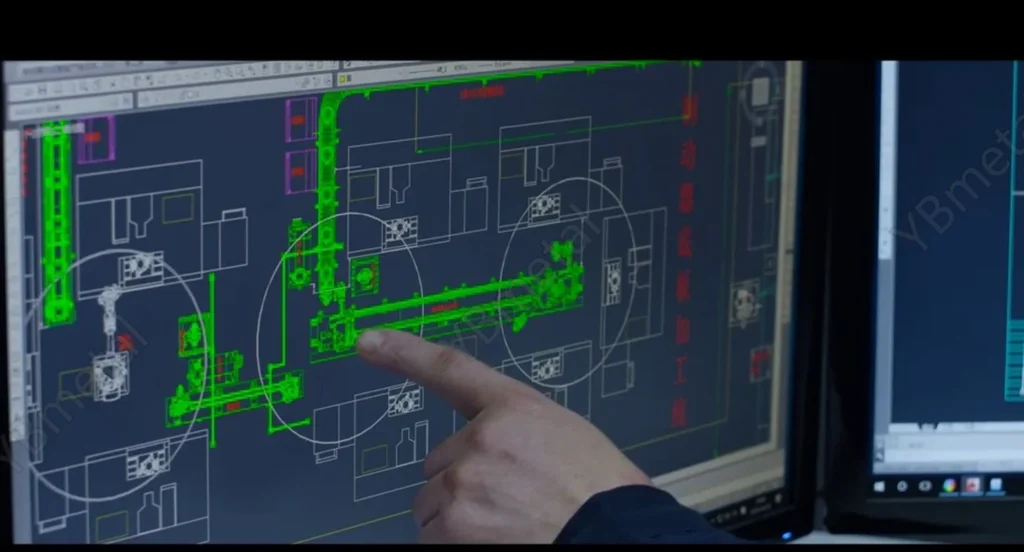

YBMETAL partners with ISO-certified foundries equipped with full shell molding lines, including:

- Metal pattern tooling (for shell molds)

- Automatic sand coating & shell core machines

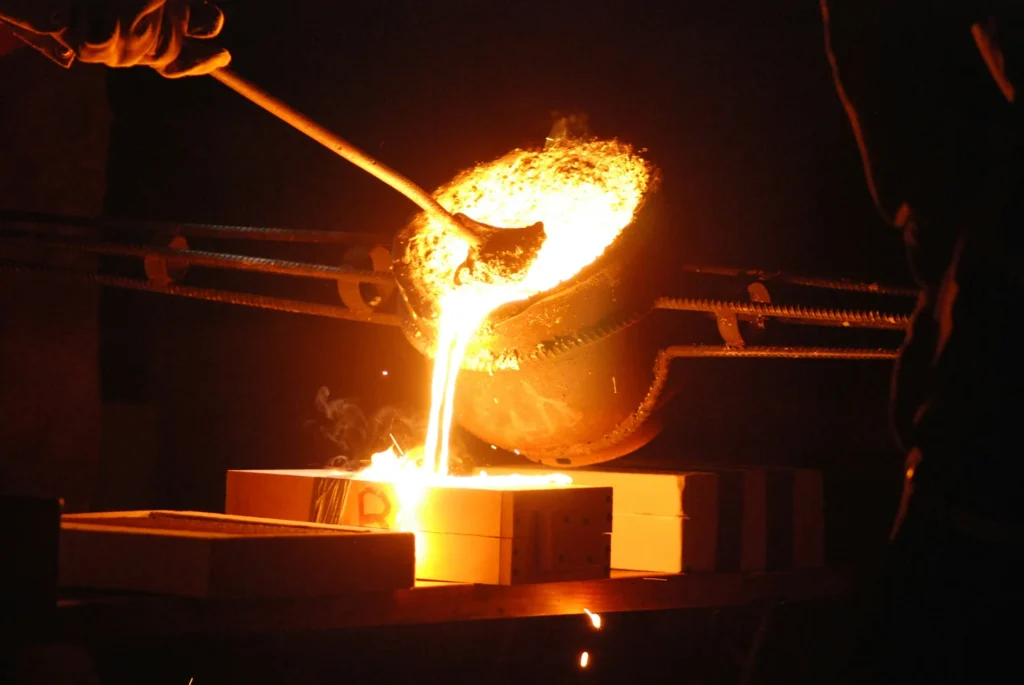

- Melting via electric induction furnaces

- Shell mold assembly & pouring systems

- Sand blasting, grinding, and heat treatment

This ensures a seamless process, from shell mold design to finished machined castings.

Typical Products Made with Shell Molding

We supply shell-molded iron castings that are CNC machined and ready for export:

- Cast iron exhaust manifolds, brake calipers, and flanges

- Ductile iron gear housings, pump bodies, and valve parts

- Agricultural and tractor components

- Machined gray iron brackets, pipe parts, and engine supports

This process is preferred for castings used in pumps, valves, housings, manifolds, flanges, and other OEM parts that demand machining and documentation.

Ductile Iron Foundry China

Ready to Source Shell Molding Iron Castings?

If your part requires tight-tolerance iron casting, fine surface finish, and machinability, shell molding is the right solution.